Max Cleaning Diameter

10m

Flow Rate Range

38 - 409 L/min

Pressure Range

2 - 10 bar

Description

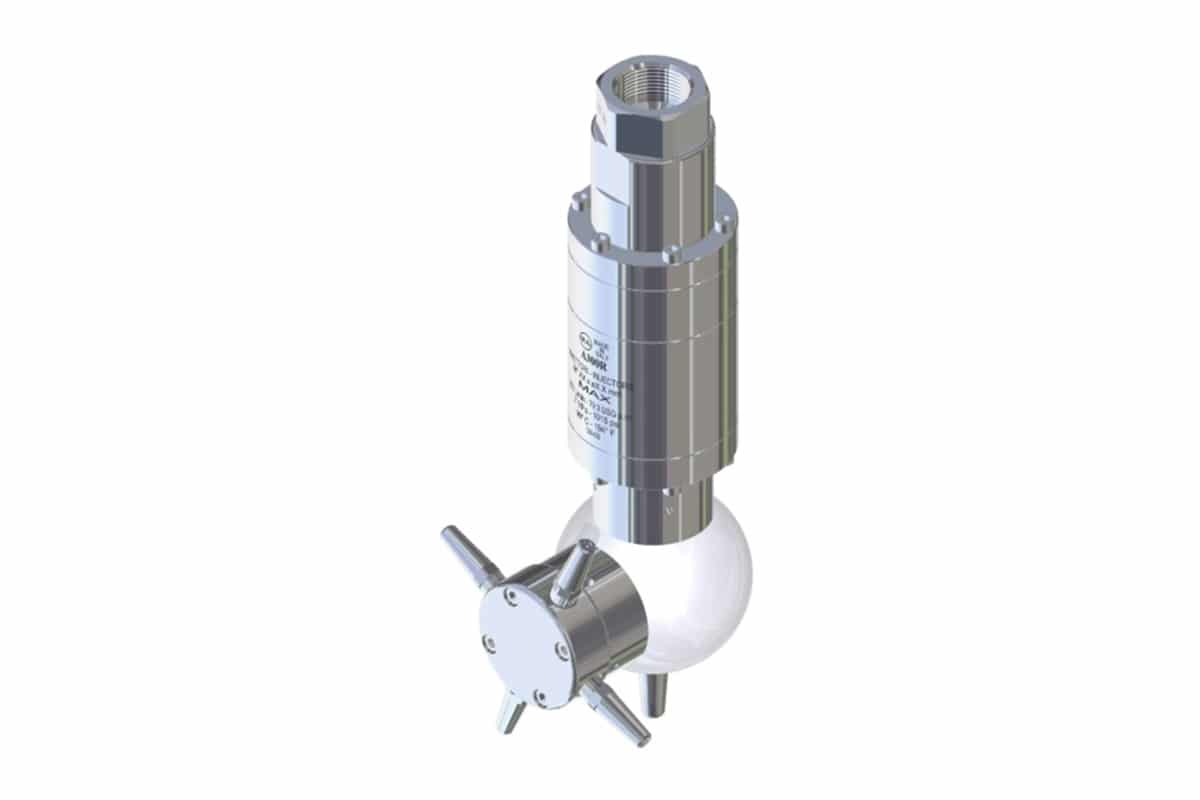

The rotating jet cleaner Turbo SSB 40 & 125 take the popular slotted spray ball format into its next evolutionary phase by removing the ball bearings and slowing the rotation speed down. The tank washer Turbo SSB 75 is designed for tank inside cleaning and stationary installation. This unit has been designed for operation in the vertical position with the inlet connection at the top. Operation in any other position may adversely affect the unit’s performance.

Advantages

- Slow, Constant Rotation

- Ball Bearing Free- Increased Service Life

- High Efficiency Fan Jets

- FDA conform

- Optional ATEX exempt

- Available for tank safety system VARITOP®

- Economic Flow Rates (SSB 40,75)

- SIP through the nozzle possible (SSB 125)

- Preferred mounting position: vertical down (SSB 40, 125)

Operation

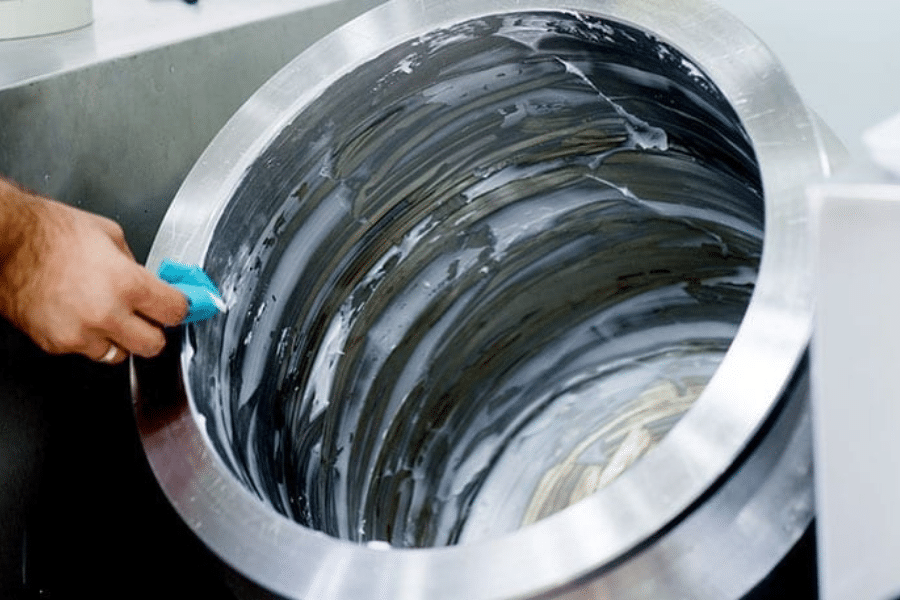

Wash fluid is directed through the slots on the rotating ball, producing independent strong fan jets giving total coverage. Each fan jet targets a specific area of the vessel. Ideal for burst rinsing or prolonged washing with instant, strong impact performance.

Applications

Ideally suited to low flow, low pressure applications where a slow constant rotation speed is required to give longer chemical dwell times for improved cleaning efficiency. The tried and tested design makes the units truly versatile across any industry sector. The units are suitable for cleaning small/medium size vessels and manufacturing equipment. Compact in design, effective in performance, they meet all hygienic design requirements, which makes them highly suitable for the pharmaceutical, and biotech industries as well as food, beverage and other hygiene conscious industries.

| Turbo SSB 40 | Turbo SSB 75 | Turbo SSB 125 | |

| Recommended pressure | 2 – 5 bar (29 – 72.5 psi) | 2 – 10 bar (29 – 145 psi) | 2 – 6 bar (29 – 87 psi) |

| Cleaning diameter | up to 3 m (9.8 ft) | max. 4.7 m (15.4 ft) | max. 10 m (32.8 ft) |

| Flow rate | 2.1 – 3.7 m³/h 38.3 – 61.7 l/min 10.1 – 16.3 USgpm | 3.6 – 9.2 m3/h 60 – 153.3 l/min 15.85 – 40.5 USgpm | 12.0 – 24.5 m³/h 200 – 408.3 l/min 52.8 – 107.9 USgpm) |

| Spray pattern | 360° | ||

| Operating temperature | max. 90 °C (194 °F) | ||

| Ambient temperature | 140 °C max. (284°F), 30 min | 140 °C max. (284°F), 30 min | SIP max. 140 °C (284 °F), 30 min |

| Insertion opening | BSP / NPT min. 38 mm (1.5 inch) min. /Pin Fix 57 mm (2.24 Inch) | Turbo SSB 75 BSP/NPT min. 60 mm (2.36 inch) / Pin Fix min. 90 mm (3.54 inch) Turbo SSB 75 CS BSP/NPTmin. 45 mm (1.77 inch) / PinFix min. 90 mm (3.54 Inch) | BSP / NPT min. 90 mm (3.54 inch) Pin Fix min. 110 mm (4.33 inch) |

| Materials | Stainless Steel 316L(1.4404), PTFE or C-PTFE | ||

| Pipe connection | 3/8″ BSP or NPT Female optional Pin Fix for½” OD (12.7 x 1.6) &DN 15 (19 x 1.5) tube | ¾” BSP op NPT Female, optional Pin Fix for 1″ OD (25.4 x 1.6) & DN 25 (29 x 1.5) tube | 1¼” BSP or NPT female, optional Pin Fix for 1½” OD (38.1×1.6 mm) & DN 40 (41 x 1.5 mm) pipe |

| Weight | approx. 0.11 kg (0.24 lbs) | approx. 0.35 kg (0.77 lbs) | approx. 0.9 kg (1.98 lbs) |

Product Reviews

There are no reviews yet.