IBC Washing

Founded in 1982, Tecpro Australia has developed an enviable reputation for providing reliable and cost-effective technical solutions for a vast range of industrial applications. Products suitable for IBC Washing application include:

* Spray Nozzles

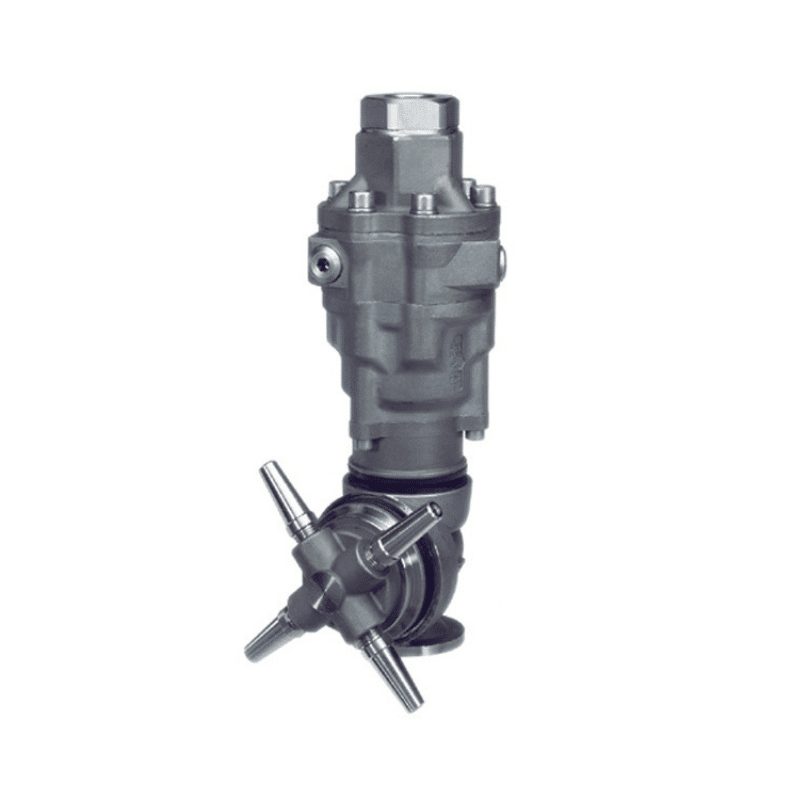

* CIP Tank Cleaning

* Design, Fabrication & Consulting

Our customers benefit from the following:

• Access to a broad range of quality solutions and technical advice

• Local sales support and customer service with a focus on integrity and honesty

• Over 30 years’ experience of providing expertise and solutions

• Quality European manufactured products.