Static vs. Rotating Tank Cleaning Nozzles

January 31, 2023

Whatever is being produced at scale, from foodstuffs to beverages, manufacturers are required to clean their tanks thoroughly to avoid contamination and meet health and safety standards. This is mostly done via a clean-in-place method using different types of spray nozzle technology, to avoid dismantling and rebuilding the equipment that needs cleaning. Clean-in-place also prevents an operator having to enter tanks or other confined space to manually clean. In this article we’ll outline the differences between static and rotating tank cleaning nozzles, to help determine the most cost-effective and efficient solution that fits within both financial and environmental targets.

Tank cleaning nozzles are industrial quality equipment, specifically designed for washing and sanitizing tanks, cans, scrubbers and containers of all sizes. These tank washing nozzles for the most part, can divided into two types: static or rotating. The rotating type can be divided into free-spinning, controlled rotation, or gear controlled.

What are the differences between the two types of tank cleaning nozzles and when should you choose a static tank cleaning head over a rotating one?

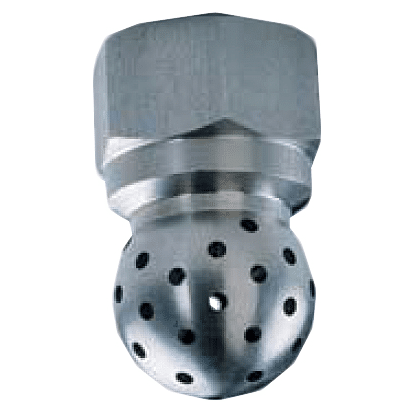

Static Spray Nozzles (Spray Balls):

This is the most basic form of tank washing device, used across many industries for its reliability. Liquid from the static spray nozzle hits the tank interior in a pre-defined cleaning pattern which is fixed as a result of holes being drilled into the nozzle. This freefalling film then cleans the tank walls, however, it takes a relatively long time and can result in excess water/chemical usage. Its low-impact and high-volume fluid requirement limits its use to small tanks and processes where easily cleaned liquids and non-sticking products have to be rinsed.

Free Spinning (Rotating Spray Nozzles):

The free-spinning rotating spray nozzle offers a rotating spray pattern. The liquid itself drives the movement, which cascades and wets the internal surfaces of the tank walls. The fan pattern creates a vibration off the tanks’ internal surfaces, agitating the residue making it easier to remove. This rotating spray nozzle can reduce water and chemical usage by up to 30% compared to static spray nozzles, whilst also cleaning the tank faster and consequently reducing downtime. Worth noting, though, that the operating pressure has a direct influence on the rotation speed. It must be limited to prevent the liquid jets from breaking into minute droplets, losing part of their impact value on the wall. While these rotating spray nozzles are suitable for larger tanks with a wetting radius of up to 6m, it may not clean harder to clean residues effectively, but does offer a 360° guaranteed repeatable cleaning coverage.

Controlled and gear-controlled rotation nozzles are kept in motion by a friction motor and therefore generate high-impact water jets that clean the inside of the tank in a guaranteed repeatable predefined pattern, removing even the most stubborn of residue, effectively cleaning the entire tank surface with high mechanical impact. This nozzle technology can provide additional efficiencies such as reducing water and chemical usage, whilst reducing cleaning cycle times.

So, which is best?

Each application may require a different approach. When choosing the right cleaning head for your application there are a few questions to consider.

- Is the product water-soluble and easy to clean?

- What size is the tank?

- Are there any obstacles in your tank which might shadow areas from direct cleaning fluid impact?

- Is reducing water and chemical usage a company focus?

As a rule of thumb, when carrying out simple cleaning tasks in smaller tanks or vessels that require a simple rinse, the fixed or static spray nozzle continue to provide excellent cleaning, so if the product is water soluble and has light residue to remove, this might be a good option. If you have high flow rates, fixed spray balls can also be a good solution, however, for larger or more complex tanks, rotational spray nozzles use less water, have faster cleaning cycles and use fewer chemicals. Their flat fan or jet spray pattern penetrate a larger surface area inside the tank with greater impact. Moreover, droplets created by controlled rotation nozzles spray nozzles are larger and strike at higher speeds, which enable them to remove tough heavy soiling.