How to Choose the Right Atomising Spray Nozzle

October 18, 2022

Do you need to know how to find the correct air atomising spray nozzle for your application needs? Choosing the right atomiser can seem overwhelming, but we’ve simplified the process below with 5 things to consider when making the decision.

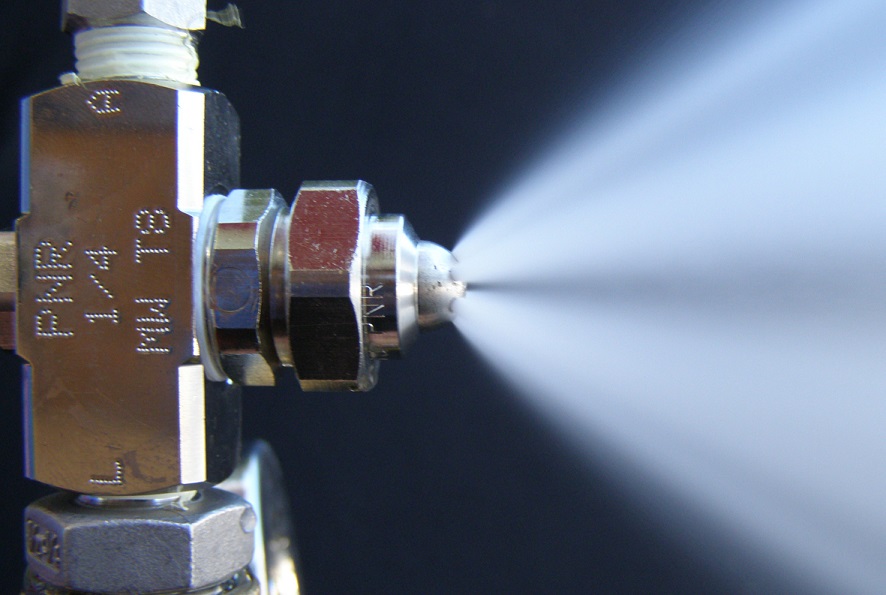

First up, let’s talk about what an atomising spray nozzle is. Put simply, an atomiser nozzle is a tool that generates a spray of liquid mist, essentially fragmenting liquid into very fine droplets.

Uses for Atomising Spray Nozzles:

Uses could be anything from dust suppression, cooling and humidification through to cleaning and disinfection. Depending on the application, you will be looking for either a pneumatic (air assisted) or a hydraulic (liquid only) atomising spray nozzle.

Hydraulic vs Pneumatic:

- A hydraulic atomising spray nozzle is capable of fragmenting liquid even at low pressures using only liquid. It relies on pressurised liquid being forced through a small passage to atomise and create the spray. It’s simple to set up and you only need to worry about your water supply for this to work.

- Pneumatic spray nozzles (also known as air atomising spray nozzle) use liquid as well as compressed air to assist in atomising the liquid. Pneumatic spray nozzles can provide finer atomisation and can spray a lower, more controlled volume of liquid. Consideration is that the set up can be more complicated and more costly due to the need for a compressed air supply.

For the purpose of this article, we will focus on air assisted atomising nozzles.

Internal Mix or External Mix:

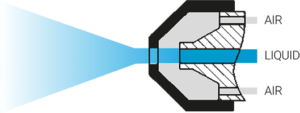

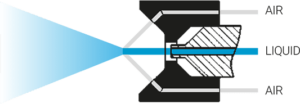

Important to note that pneumatic atomising nozzles mix air with liquid flow, breaking up the fluid into smaller droplet particles and there are two kinds of set-ups; The first is external, where the liquid and gas are sprayed by separate orifices and the mixing occurs outside the nozzle, meaning pressure values can be adjusted independently of each other and flow rates can be easily controlled. The second is internal, where the atomiser unit is designed so that the liquid and air are combined inside, and the resulting atomised flow is sprayed by the orifice/orifices of the nozzle.

With internal mixing, the increase in air-flow rate will cause a decrease in the flow rate of the liquid with finer drops and can produce fan or cone patterns. External mixing, allows atomisation of viscous liquids or those which contain solids in suspension, but the external mix units can generate only a flat jet.

Internal Mix Atomiser

External Mix Atomiser

Choosing the right spray nozzle:

When choosing an atomizing nozzle, you need to consider its intended application, supply pressure, and position. With many variables involved, which spray nozzle will offer the right solution for your application? Here are our five tips help you make the right choice:

- What resources are at your disposal?

Is there a pressurised liquid source available or only a compressed air source available? no pressurised liquid supply, you will need a gravity or siphon-fed (pneumatic) nozzle. There are some drawbacks to consider with this option; siphon-fed nozzles are best suited for applications that require continuously spraying a low viscosity liquid at a low volumes It is also possible to use a pressure vessel for liquids in some applications.

- What’s the viscosity of the liquid are you wanting to spray?

Another factor when choosing between nozzles is the viscosity (thickness) of the liquid it will need to spray. Depending on the type of air atomising spray nozzle you choose, as mentioned above, they can complete the atomising process either inside the nozzle chamber (internal mixing) or outside the nozzle chamber (external mixing) External nozzles are more suited to thicker, more viscous liquids. Having said that, if the viscosity is normal, internal mixing will provide more spray options such as cone patterns.

- Define the flowrate of the fluid you are using in litres per hour

If your application requires a set volume of liquid, you can choose the correct nozzle based on its flow rate. As a rule, external-mix nozzles inherently dispense more liquid than internal-mix nozzles, as they have fewer restrictions on the liquid flow. For applications requiring higher volumes, a liquid-only atomising nozzle will provide an increase in litres per hour. However, using liquid-only nozzles will increase your droplet size.

- Optimum droplet size.

Finer droplets are crucial in many atomising nozzle applications. Benefits include even distribution and liquid conservation. Internal-mix nozzles excel at providing the smallest droplet size possible. External-mix and liquid-only nozzles produce larger droplet sizes, but do increase the volume sprayed, so knowing what is more important here is key.

- Impact force.

The impact force is the force generated by the jet of water deflected by the impact surface and its strength is often expressed in kg/cm2 or lb/inch2. The type of nozzle being sprayed can influence impact. A solid stream nozzle and flat fan nozzle spray from the same distance at the same pressure and flow rate. However, the solid stream nozzle provides more impact than the flat fan nozzle because the solid stream is concentrating more flow per area than the flat fan nozzle.

The wrong choice in spray nozzles can lead to ineffective spraying, liquid or product wastage and reduced performance, neither of which is a result you want. If in doubt, we are here to assist in the right choice for your application. Speak to one of the Tecpro experts today!