Humidification

Humidification sprays or humidification systems are designed to add moisture to the air in indoor environments to maintain or control humidity levels. These systems are commonly used in various settings, including residential, commercial, industrial, and agricultural spaces, where maintaining proper humidity is essential for comfort, health, and specific processes. Here are key points about humidification sprays:

1. Purpose of Humidification:

- Comfort and Health:

- Humidification is often used to prevent the air from becoming too dry, especially in climates with cold winters or in air-conditioned spaces, where heating or cooling systems can reduce humidity levels.

- Protecting Wooden and Musical Instruments:

- Maintaining proper humidity is crucial for preserving wooden furniture, musical instruments, wine barrels and other items that can be affected by changes in moisture levels.

- Industrial Processes:

- Some industrial processes, such as printing, digital, textile manufacturing, and certain chemical processes, require controlled humidity levels for optimal results.

- Agricultural and Horticultural Applications:

- Humidification is used in greenhouses and agricultural settings to create optimal conditions for plant growth.

2. Types of Humidification Systems:

- Evaporative Humidifiers:

- These systems use a wick filter or a rotating drum to absorb water, which is then evaporated into the air using a fan.

- Common in residential humidifiers.

- Ultrasonic Humidifiers:

- Ultrasonic humidifiers use ultrasonic vibrations to produce a fine mist of water, releasing it into the air.

- These are often quieter than evaporative humidifiers.

- Steam Vaporizers:

- Steam vaporizers heat water to create steam, which is then cooled slightly before being released into the air.

- Effective for large spaces.

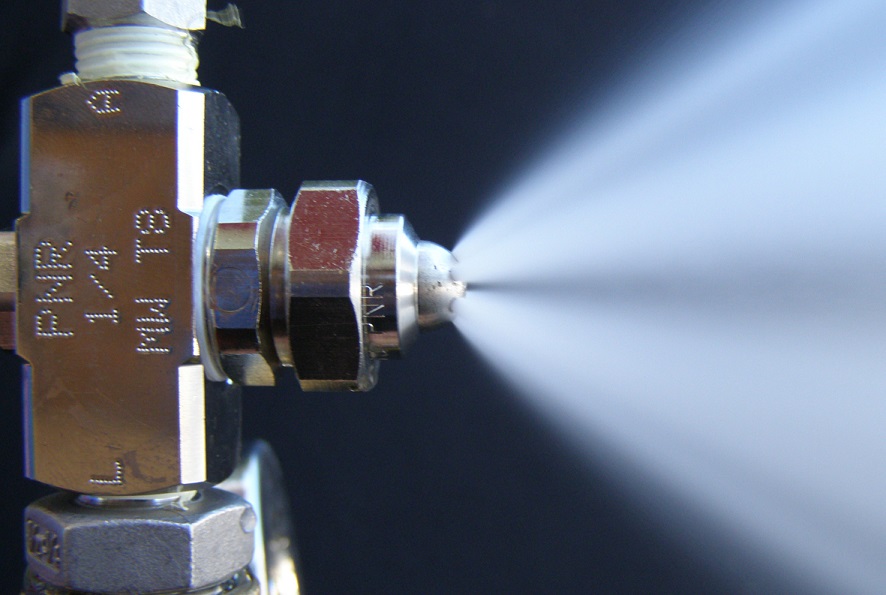

- Spray or Misting Systems:

- Humidification sprays or misting systems use water spray nozzles to release fine droplets into the air, increasing humidity levels.

- Commonly used in commercial and industrial applications.

3. Components of Humidification Sprays:

- Water Supply:

- Humidification systems require a water source, which can be tap water, filtered water, or, in some cases, demineralized water to prevent mineral buildup in the system.

- Spray Nozzles:

- The spray nozzles disperse water into fine droplets, allowing for efficient evaporation and humidification.

- Control System:

- Many humidification systems have a control system that monitors humidity levels and adjusts the operation of the system accordingly.

- Pumps and Fans:

- Pumps and fans may be used to circulate water and distribute the mist more effectively, especially in larger spaces.

- Filters:

- Some systems may include filters to remove impurities from the water before it is released into the air.

4. Considerations:

- Maintenance:

- Regular cleaning and maintenance of humidification systems are essential to prevent the growth of mould and bacteria.

- Humidity Control:

- Some systems allow for precise control of humidity levels to meet specific requirements.

- Location:

- The placement of humidification systems and the direction of mist dispersion should be considered to achieve uniform humidity distribution.

- Health Considerations:

- Proper maintenance is crucial to prevent the release of contaminants into the air, which can impact respiratory health.

Humidification sprays play a vital role in creating comfortable and healthy indoor environments, particularly in regions with dry climates or during seasons when indoor heating or cooling systems can reduce humidity levels. The selection of a humidification system depends on the specific needs of the space and the desired level of control over humidity conditions.