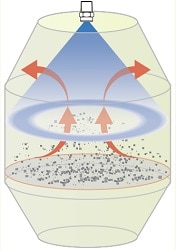

A hollow cone spray pattern is made of droplets concentrated on a ring-shaped impact area, with no droplets falling inside the cone. Under the same operating conditions, hollow cone nozzles produce a very fine atomized liquid mist and can capture a higher rate of suspended particles than other styles. They are widely used in exhaust scrubbers and gas cooling.

TYPES OF HOLLOW CONE NOZZLES

HOLLOW CONE (Turbulence Cone)

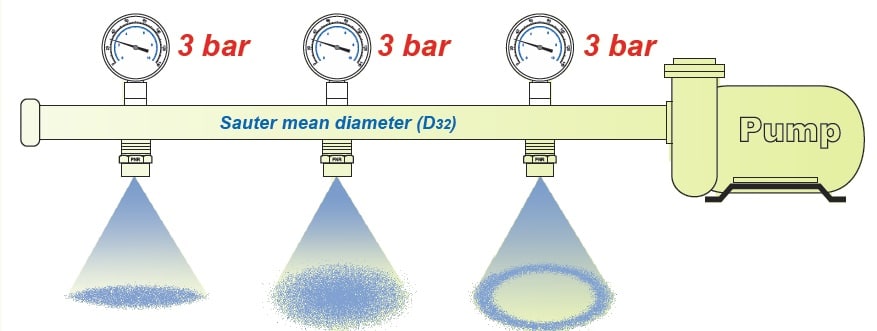

These nozzles use a tangential injection of liquid into a whirling chamber to generate centrifugal forces which break up the liquid vein as soon as it leaves the orifice. Precisely designed orifice profiles, making use of the Coanda effect, provide the ability to obtain very large spray angles.

HOLLOW CONE (Deflection Cone)

A hollow cone can also be obtained taking a liquid flow to change direction onto a properly designed surface in order to break the liquid into droplets and distributes them as a hollow cone spray pattern with clog resistance. This kind of nozzle is mainly used for applications in fire-fighting systems.

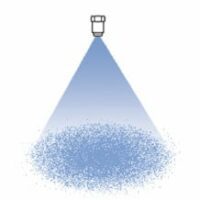

Mist Spray

Hollow cone nozzles provide a finely atomized mist and a very uniform hollow cone spray pattern. They are ideal to capture suspended particles and offer higher performances than other nozzles with same operating pressure and capacity. These nozzles are widely used for their efficiency in cooling and cleaning of gases, dust control, absorption processes and air-humidification.

Poor Gas Scrubbing Efficiency?

Hollow cone nozzles produce a ring-shaped spray pattern where all the liquid jet is concentrated on the outer edge of the ring. Users may fear that offset nozzles do not catch all suspended particles because air flows through directly from the centre. Hollow cone sprays are the solution to this problem as their fine mist spray provides a better scrubbing effect.

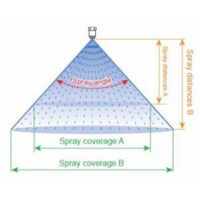

Accurate Offset and Overlap

The correct positioning of hollow cone nozzles is of vital importance, there are matrix and offset settings, details of which can be found on the full cone spray engineering page.