A flat fan spray nozzle serves the purpose of spraying onto a surface or an object moving in a transverse direction with respect to the direction of the jet, a typical example being the nozzles in a car washing tunnel. The vast majority of flat spray nozzles used in the industry work according to one of the following principles.

TYPES OF FLAT FAN NOZZLES

INLINE FLAT FAN (Pressure nozzle):

This is the general purpose flat fan nozzle where the liquid enters the nozzle in line with the axis length and is fed to a pressure chamber from where it is ejected through the nozzle orifice. Flow value and spray angle are determined respectively from the orifice cross section and the orifice edge profile.

INLINE STRAIGHT JET (Pressure nozzle):

Straight nozzles can be considered as flat fan nozzles as the only difference is the spray angle which is zero degrees in solid jet nozzles. These nozzles are often used in high-pressure operating environments where the wear resistance of the nozzles is very important. It ensures optimum service life and spray orientation. Apart from the standard brass, 303SS and 316SS, Tecpro offers these nozzles in a wide range of wear resistant materials including

-

- 416 Hardened stainless steel

- Ruby orifice with SS body

- Tungsten carbide nozzle tip with SS body

SPOON OR DEFLECTIVE FLAT FAN (Impact nozzle):

These nozzles produce a flat fan spray based on a jet of water leaving a round orifice then impacting and deflecting of a surface. According to the different arc design of the deflective surface, these spoon flat fan nozzles can be produced in two types: high impact with narrow spray angle or low pressure with wide spray angle.

- Under the same operating conditions, narrow angle high impact nozzles produce a higher impact force than standard flat fan nozzles. They are suitable for cleaning environments that need strong impact such as to remove caked on solids.

- Low pressure nozzles with wider spray angle produce a 130° spray angle and a large area of water curtain effect. Low-impact spray nozzles are widely used in various applications such as foam removal, water curtain for gas separation, fruits and vegetable cleaning and residential fire protection.

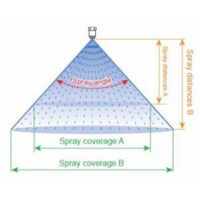

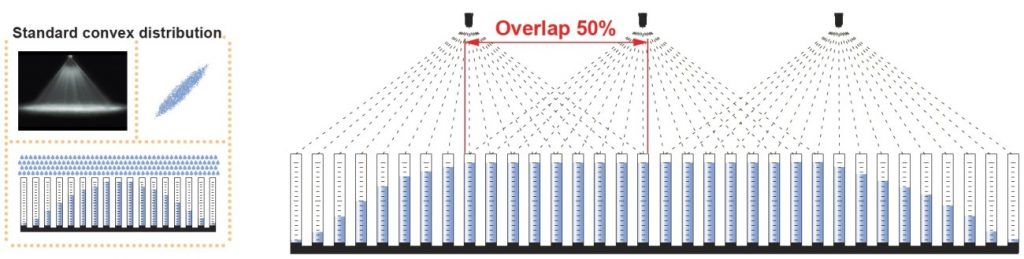

CORRECT OVERLAPPING

When several nozzles are used to spray an area, it’s very important to produce a uniform spray distribution across the nozzles. The correct spray overlapping methods are shown here below.

CONVEX DISTRIBUTION OVERLAP

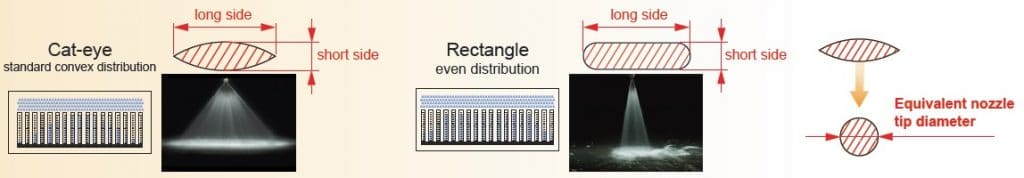

In a standard convex spray distribution the medium section has a larger capacity than the two lateral sections. It’s necessary to overlap 50% of the spray range.

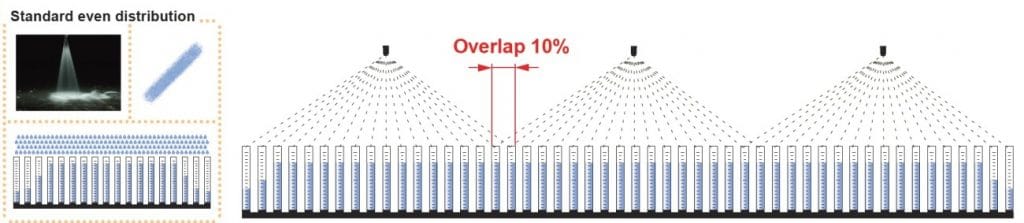

EVEN DISTRIBUTION OVERLAP

An equal distribution provides a uniform spray and 10% of the spray range overlaps.

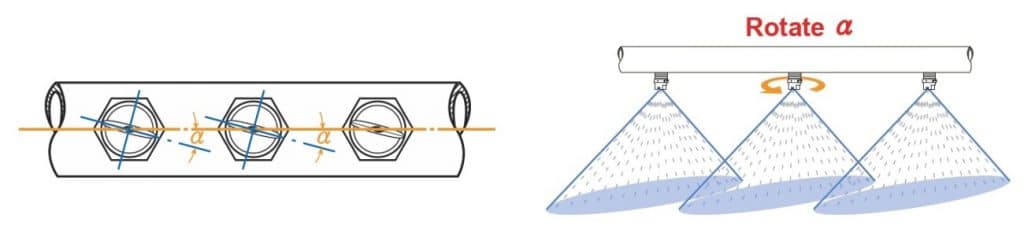

OFFSET

A flat fan nozzle produces a high impact jet with a 5°-15° offset angle to avoid overlapping and interference. The offset angle depends on the spray range of the flat fan nozzle.

- 15°~60° spray angle = 5°~10° Offset (α)

- 60°~120° spray angle = 10°~15° Offset (α)

Flat fan nozzles – Low pressure, wide angle

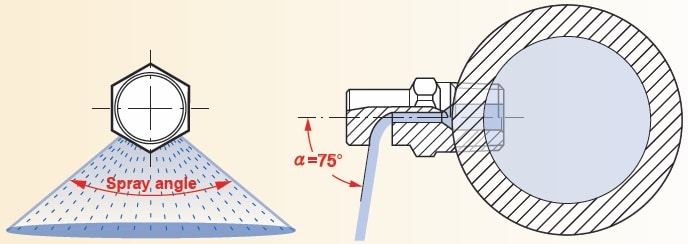

K series nozzles work on the principle of jet deflection, conveying the liquid against an accurately machined sloping surface to change the flow direction and produce a fan-shaped mist with a 75° angle to the inlet of the nozzle. Medium-sized droplets and medium/low impact values.

Flat fan nozzles – High impact

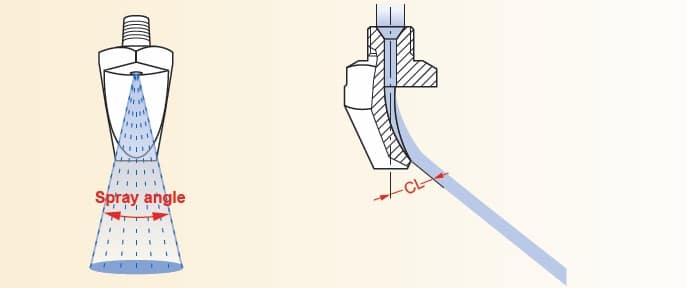

K nozzles high-impact type work on the principle of jet deflection. The liquid flow is conveyed onto a deflection sloping surface specially designed to produce a high impact narrow flat fan and medium-sized droplets. They are widely used in operating environments requiring high impact spray jets. Moreover, their rounded orifice and free inside passage minimize the risk of clogging. There is a specific angle that must be kept to ensure spray direction (see ~ CL).

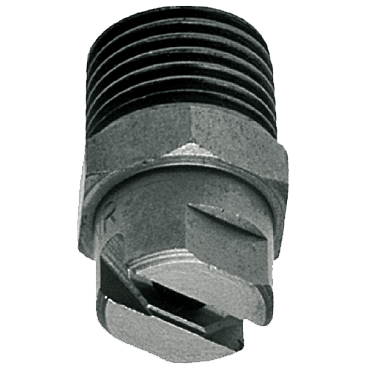

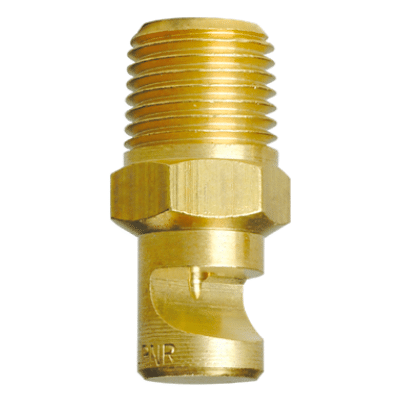

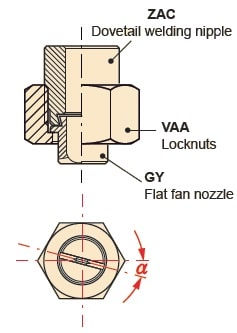

Dovetail flat fan nozzle

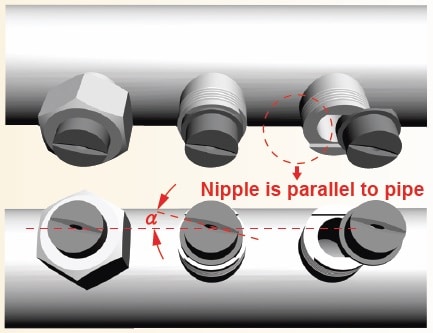

Flat fan nozzle tips provide a high impact spray. Adjacent nozzles must rotate with a specific offset angle to avoid interference and produce a uniform spray coverage when their jets overlap. For the GY series nozzle tips an offset angle ~α must be set between the spray plane and their dovetail guide.

Their specific dove-tail design ensures the correct spray direction and allows time saving as spray angles must not be adjusted each time. For thread size 3/8″ offset angle is 5°. For thread size 3/4″ offset angle is 15°. The picture to the right shows an offset angle ~α between the spray plane and the dovetail.

Equivalent orifice diameter

Flat fan nozzles produce cat-eye shaped or parabolic distribution patterns with different capacities. Hence nozzle tips have long and short side differences. For convenience reasons, their “cat-eye shaped” spray pattern is converted into the area of a circle. The datum so obtained from the conversion is called “equivalent nozzle tip diameter”.

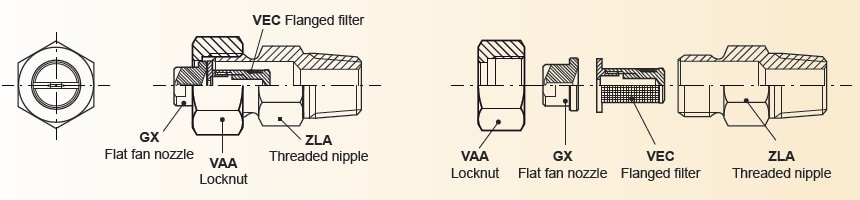

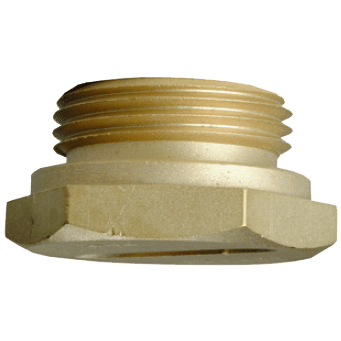

Flanged nozzle

Flanged nozzles have no thread. The nozzle tip is installed on a welding nipple and fastened with a locknut. The scope of their design is:

1. Easy adjustment of the spray direction

2. Easy maintenance