ROM Bin Dust Suppression

How To Suppress ROM Bin Dust

ROM Bins or dump hoppers can be a particularly problematic area for dust generation during mineral processing at mine sites, quarries and other material processing facilities. Dust is generated by the transfer of materials into the hopper, such as a truck or rail dumping as well as the dust generated by the impact of the material as it lands in the hopper which displaces large amounts of dust-laden air forcing it up and out of the hopper.

The most effective means of dust suppression for this area of processing will vary from site to site depending on the type of product and properties of the dust it produces, quality of the available water supply and (if possible) compressed air supply, environmental conditions as well as other influencing factors. Generally, the team at Tecpro Australia designs the dust suppression system to create a suitable mist curtain to contain as much dust within the hopper during the dumping process as well as a fog of fine droplets to help capture any airborne dust particles.

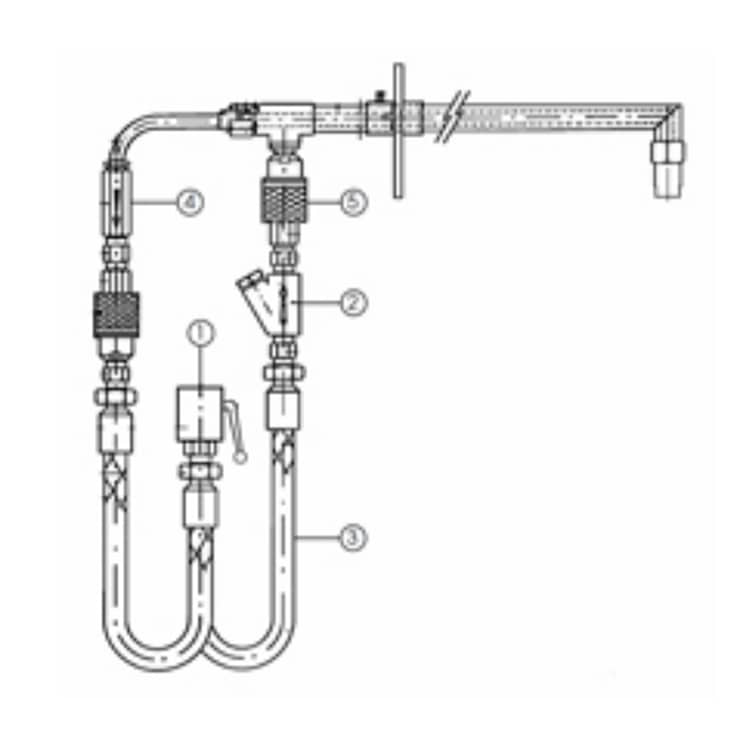

For the dust containment component of the spray system, we use flat fan nozzles such as the J type standard flat fan nozzle. For air assisted atomising systems we use external mix flat fan nozzles and dry fog ultra sonic atomisers. Nozzles used for the airborne particles vary depending on application specifics and requirements though usually are hollow cone nozzles or air assisted atomisers.

For large ROM bins where a greater mist throw distance is required for complete coverage we can offer options such as the H1 swing atomiser or even small fan driven dust control cannons like the V7 Dust Controller.

ROM Bin dust suppression systems are generally triggered by the approaching truck passing a sensor which activates the sprays for a pre-determined period. This helps to conserve water and reduce over-saturation of the product which could cause issues further down the processing line.