Drying & Blow off

Drying and blow off processes in industrial settings are essential for removing moisture, liquids, or debris from surfaces, products, or equipment. These processes are employed across various industries to achieve product quality, maintain cleanliness, and ensure efficient production. Drying is the removal of moisture or liquid, while blow-off involves the use of compressed air or other gases to remove debris or liquids from surfaces.

1. Applications of Drying and Blow-Off:

- Manufacturing: Drying and blow-off processes are integral in manufacturing operations, ensuring that products meet quality standards by removing liquids or contaminants.

- Cleaning: Blow-off is often used as a cleaning method to remove dust, particles, or debris from surfaces or products.

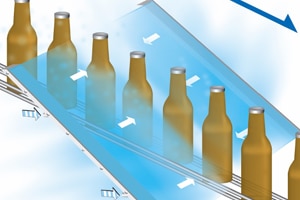

- Food and Beverage: In the food and beverage industry, drying is critical for ensuring product quality and safety. Blow-off is used to remove excess liquids from food items or packaging.

- Printing: Drying is essential in the printing industry to set inks on paper or other substrates. Blow-off may be used to remove dust or debris before printing.

- Automotive: Drying and blow-off are employed in automotive manufacturing for tasks such as drying painted surfaces, removing contaminants from vehicle bodies, or preparing surfaces for coating.

2. Drying Methods in Industry:

- Air Drying: In many industrial processes, simply allowing air to circulate around products or surfaces can facilitate natural drying. This method is common in applications where time is not a critical factor.

- Forced Air Drying: In forced air drying, nozzles, blowers or fans are used to direct air onto surfaces to accelerate the drying process. This method is common in painting, coating, and drying applications.

- Infrared Drying: Infrared drying uses infrared radiation to transfer heat directly to the surface, promoting quick evaporation of moisture. It is often used in applications where precise control over drying is required.

- Microwave Drying: In some industrial settings, microwave drying is employed to heat the material directly, promoting rapid moisture removal.

3. Blow-Off Methods in Industry:

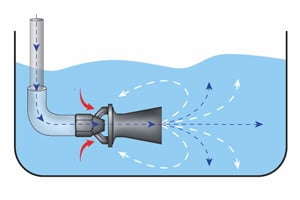

- Compressed Air Blow-Off: Compressed air is widely used for blow-off applications. Air blow-off nozzles or air knives release high-velocity compressed air to remove liquids or debris from surfaces.

- Centrifugal Blowers: Centrifugal blowers create a high-velocity air stream and are often used in applications where a significant volume of air is required.

- Vacuum Systems: In certain applications, vacuum systems may be used for blow-off by creating a negative pressure that draws away liquids or particles.

4. Equipment Used in Drying and Blow-Off:

- Air Knives: Air knives are devices that use compressed air to create a thin, high-velocity air stream. They are commonly used for drying or blow-off applications.

- Blow-Off Nozzles: Blow-off nozzles are designed to release compressed air in a controlled and targeted manner to remove liquids or debris from specific areas.

- Blowers and Fans: Centrifugal blowers and axial fans are employed to generate large volumes of air for drying or blow-off processes.

- Infrared Dryers: Infrared dryers consist of infrared lamps that emit radiant heat, promoting quick drying of surfaces or materials.

5. Benefits of Drying and Blow-Off in Industry:

- Quality Assurance: Drying and blow-off processes contribute to quality assurance by ensuring that products meet specified standards and are free from contaminants or excess moisture.

- Efficiency: These processes enhance the efficiency of manufacturing operations by reducing drying times, facilitating quicker production cycles, and improving overall throughput.

- Cleanliness: Blow-off processes help maintain cleanliness in industrial settings by removing particles, dust, or liquids that could compromise the integrity of products.

- Cost Savings: Efficient drying and blow-off processes can lead to cost savings by reducing energy consumption, minimizing waste, and optimizing production workflows.

Drying and blow-off processes are integral to various industries, contributing to product quality, cleanliness, and overall operational efficiency. The choice of methods and equipment depends on the specific requirements of the application, including the type of material, desired drying time, and the need for cleanliness or quality assurance.

Founded in 1982, Tecpro Australia has developed an enviable reputation for providing reliable and cost-effective technical solutions for a vast range of industrial applications. Products suitable for drying & blow off application include:

* Spray Nozzles

* Hose Guns & Foaming Units

* Hose Reels

* Design, Fabrication & Consulting

Our customers benefit from the following:

• Access to a broad range of quality solutions and technical advice

• Local sales support and customer service with a focus on integrity and honesty

• Over 30 years’ experience of providing expertise and solutions

• Quality European manufactured products.