CONCENTRATED HIGH IMPACT FORCE

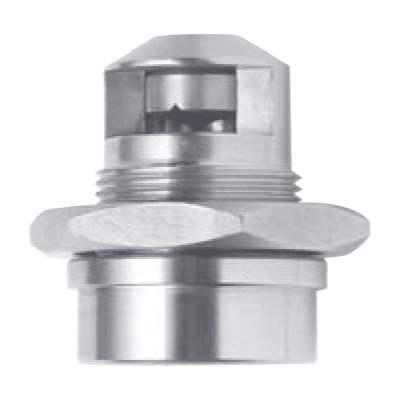

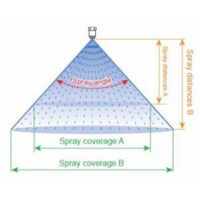

Solid jet nozzles provide a sharp and concentrated high-pressure spray jet. These nozzles offer a stronger impact force than other types at the same operating pressures and flow rates.

EXTENDED SERVICE LIFE

Solid stream nozzles are designed for applications requiring medium or high liquid pressures. High pressures may shorten nozzles service life. After long research and many application tests, our engineers found out that ruby with a second hardness level is the ideal material to overcome this problem and extend nozzles durability as it resists abrasion or scratching. The nozzle tips are precisely machined and polished to ensure a perfect solid jet and enhance performance.

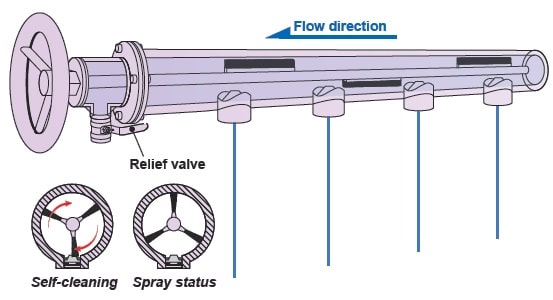

SELF CLEANING SHOWERS

Paper making requires a great deal of water. Waste water is often reused to clean filters and felts to save costs and reduce water consumption. Reclaimed water contains solids and impurities that cause nozzles clogging and shutdowns for maintenance. Self-cleaning spray pipes and nozzles are the best solution to this. Their revolutionary design helps improving a great deal both production efficiency and industrial competitiveness.

Self-cleaning spray pipes contain a rotating steel brush which can be automatically or manually operated and an escape valve at their outlet. The rotating brush removes all the dirt from the pipe walls using water.

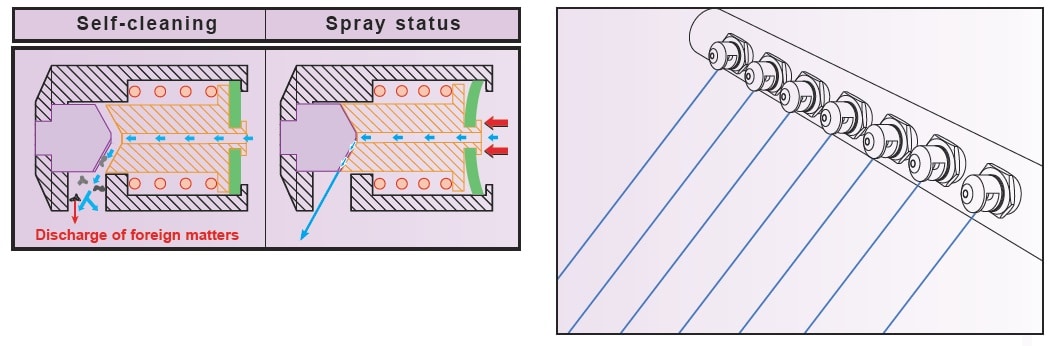

SELF CLEANING NOZZLES

The nozzle body contains a mobile piston and its opening and closing are controlled by the operating water pressure. For example, when nozzles wash mesh fabrics with an operating pressure of 3 bar, this pressure is higher than a spring force of 1 bar. Piston and nozzle body come close producing a flat fan. If the inlet pressure is reduced to 0.5 bar, lower than a spring force of 1 bar, piston and nozzle body separate opening to the maximum distance. Water pressure remains at 0.5 bar and removes any build up when back to normal condition. Self-cleaning nozzles are easy to install, align and clean and ensuring relevant time and costs savings. The spring force is set depending on customer’s plant working pressure.