Max Cleaning Diameter

1.6m

Flow Rate Range

34 - 109 L/min

Pressure Range

1 - 8 bar

Description

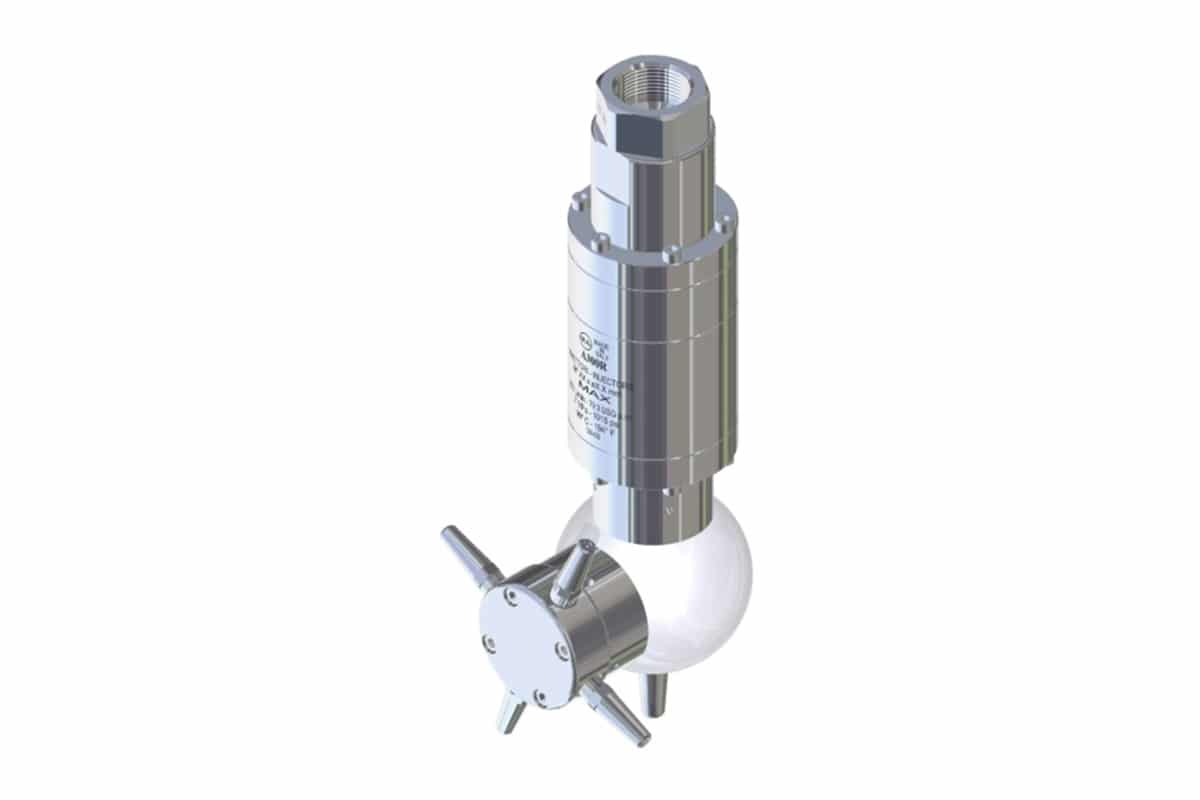

Retractable System: TANKO-RT

When baffles are a nuisance.

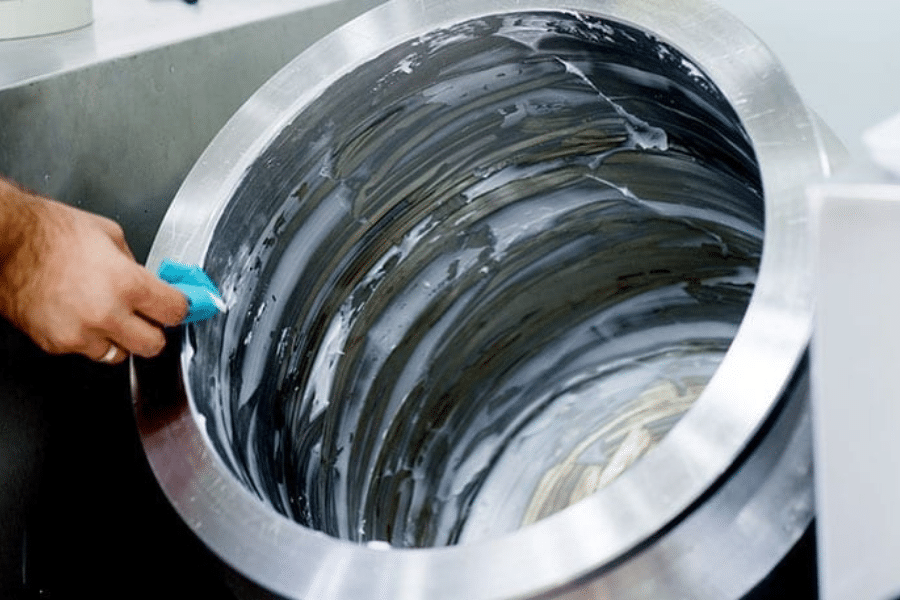

Dynamic Retractor CIP systems clean even the remotest corners. Where to attach the spray head? This question arises with nearly every CIP installation. In most cases, spray shadows caused by baffles, such as agitators, manholes, inspection glasses and a host of other muffs complicate the setup of an efficient CIP cleaning. The solution for this is a retractable cleaning systems.

An elegant solution is a so-called retractor using flood cleaners (TANKO-S or TANKO-RPB-E respectively). A pneumatic drive extends the flood cleaner to its place of operation. This in itself is nothing new: technical variations have been known on the market for many years. The AWH retractor TANKO-RT combines this fundamental idea with the modern demands on a CIP cleaning system. Depending on the cleaning head model and the working pressure, flow rates between 1 and 7 m³/h are currently possible. A detergent pressure between 1 and 8 bars can be selected.

Another important component of the TANKO-RT is the hydraulic pipe. Employing the new pipe standard DIN 11866 permitted a considerable reduction of the installation size and thus of the cavity into which the spray head is retracted.

| Material | 1.4435, 1.4401 (316), 1.4430, PTFE modified, EPDM

optional: FKM other: 1.4301 (304), PU, AI |

| Operating pressure | cleansing medium: 1 – 3 bar / 14.5 – 43.5 psi *

pneumatics: min. 5 bar / 72.5 psi, max. 8 bar / 116 psi |

|

Volume flow rate |

2 – 6.5 m³/h / 33.3 – 108.3 l/min / 8.8 – 28.6 gmp US) * |

| Cleaning radius | max. 1 m / 5.3 ft |

| Wetting radius | max. 2.5 m / 8.2 ft |

*depending on model and cleansing medium

Retractable system: TANKO-RTF 3-A Sanitary Standard certified

Some important features at a glance:

- 3-A designed

- low wear PEEK body

- slide bearing

- easy to maintain

- drainable

- designed for the food Industrie

| Material | in contact with medium: 1.4401 (316), 1.4430, 1.4435 TECA-PEEK, PTFE modified, EPDM, optional FKM

not in contact with medium: 1.4301 (304), PU, AI |

| Operating pressure | cleansing medium: 1 – 2 bar / 14.5 – 20 psi *

pneumatics: min. 5 bar / 72.5 psi , max. 8 bar / 116 psi |

| Volume flow rate | 3.3 – 4.4 m³/h / 55 – 73.3 l/min / 14.5 – 19.4 gpm (US) * |

| Cleaning radius | max. 1,5 m / 4,9 ft |

| Wetting radius | max. 2 m / 6,6 ft |

Product Reviews

There are no reviews yet.