Aeration

Aeration nozzles play a crucial role in processes that involve introducing air or oxygen into liquids, such as water treatment, wastewater treatment, and industrial applications. These nozzles are designed to facilitate the transfer of gases, typically air, into a liquid, promoting aeration for various purposes. Here’s an overview of aeration nozzles:

1. Purpose of Aeration Nozzles:

- Water and Wastewater Treatment: Aeration is a key component of water treatment processes. It helps enhance the dissolution of oxygen in water, promoting the growth of aerobic microorganisms that aid in the removal of impurities, such as organic matter and pollutants.

- Industrial Processes: Used in industrial applications to promote chemical reactions, facilitate mixing, and improve the efficiency of certain processes. It is employed in areas such as fermentation, oxidation, and biological treatment.

- Aquaculture: Aeration is critical in aquaculture to maintain optimal oxygen levels in water for the health and growth of aquatic organisms. Nozzles are used in ponds, tanks, and other aquaculture systems.

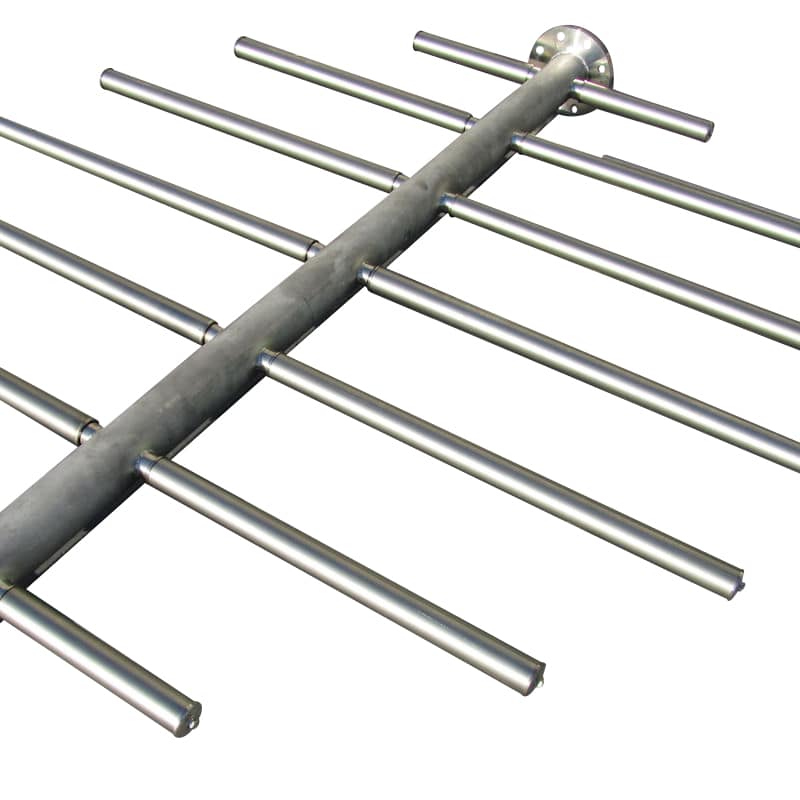

2. Types of Aeration Nozzles:

- Bubble Diffusers: These nozzles release small bubbles into the liquid, maximizing the surface area for efficient gas transfer. Bubble diffusers are commonly used in wastewater treatment plants and aquaculture systems.

- Jet Aeration Nozzles: Jet aeration involves forcefully injecting air or oxygen into the liquid through high-velocity jets. This method creates turbulence, promoting mixing and aeration simultaneously. Jet aeration is often used in industrial processes.

- Surface Nozzles: These nozzles agitate the liquid surface to enhance the exchange of gases between the liquid and the atmosphere. Surface aeration is particularly effective in promoting oxygen transfer.

- Submerged Nozzles: These nozzles are placed below the liquid surface, releasing bubbles or creating turbulence to facilitate gas exchange. Submerged aeration is commonly used in wastewater treatment plants.

3. Benefits of Aeration Nozzles:

- Improved Oxygen Transfer: Aeration nozzles enhance the dissolution of oxygen in liquid, promoting aerobic conditions necessary for various biological processes.

- Mixing and Circulation: Aeration promotes mixing, ensuring uniform distribution of gases and preventing stratification in tanks or ponds.

- Odour Control: Aeration helps in reducing the presence of foul odours by facilitating the breakdown of organic matter and the release of gases.

- Biological Treatment: In wastewater treatment, aeration supports the growth of aerobic bacteria that are essential for breaking down organic pollutants.

4. Considerations in Nozzle Selection:

- Flow Rate and Pressure: The required flow rate and pressure depend on the specific application and the volume of liquid that needs aeration.

- Bubble Size: The size of bubbles produced by the nozzle can impact the efficiency of gas transfer. Smaller bubbles generally provide a larger surface area for gas exchange.

- Material Compatibility: Nozzle materials should be compatible with the liquid and gases involved to prevent corrosion or degradation.

- Maintenance Requirements: Consider the ease of maintenance, cleaning, and replacement when selecting nozzles.

Aeration nozzles are essential components in processes that involve introducing air or oxygen into liquids for various purposes. The selection of the appropriate type of nozzle depends on the specific requirements of the application, including the desired level of aeration, flow rates, and the characteristics of the liquid being treated.

Founded in 1982, Tecpro Australia has developed an enviable reputation for providing reliable and cost-effective technical solutions for a vast range of industrial applications. Products suitable for aeration application include:

* Spray Nozzles

* Filter Nozzles

* Valves, Filters & Accessories

* Design, Fabrication & Consulting

Our customers benefit from the following:

• Access to a broad range of quality solutions and technical advice

• Local sales support and customer service with a focus on integrity and honesty

• Over 30 years’ experience of providing expertise and solutions

• Quality European manufactured products.