Tecpro Australia’s partner, PNR Italia has been manufacturing and supplying quick fit spray nozzles, swivel ball nozzles, nipples, locknuts and pipe clamps for over forty years. Many industrial facilities utilise quick-fit spray nozzles and accessories, including car wash plants, painting, phosphating and powder coating plants, machinery for washing food, rinsing containers, and many other applications.

In general, this type of product is used in industrial processes that require quick assembly and adjustment of the orientation and spray coverage of the nozzles. All of our quick fit products are adaptable to suit the most varied needs, combining a quick and easy assembly and disassembly with the ability to direct the nozzle spray in every direction.

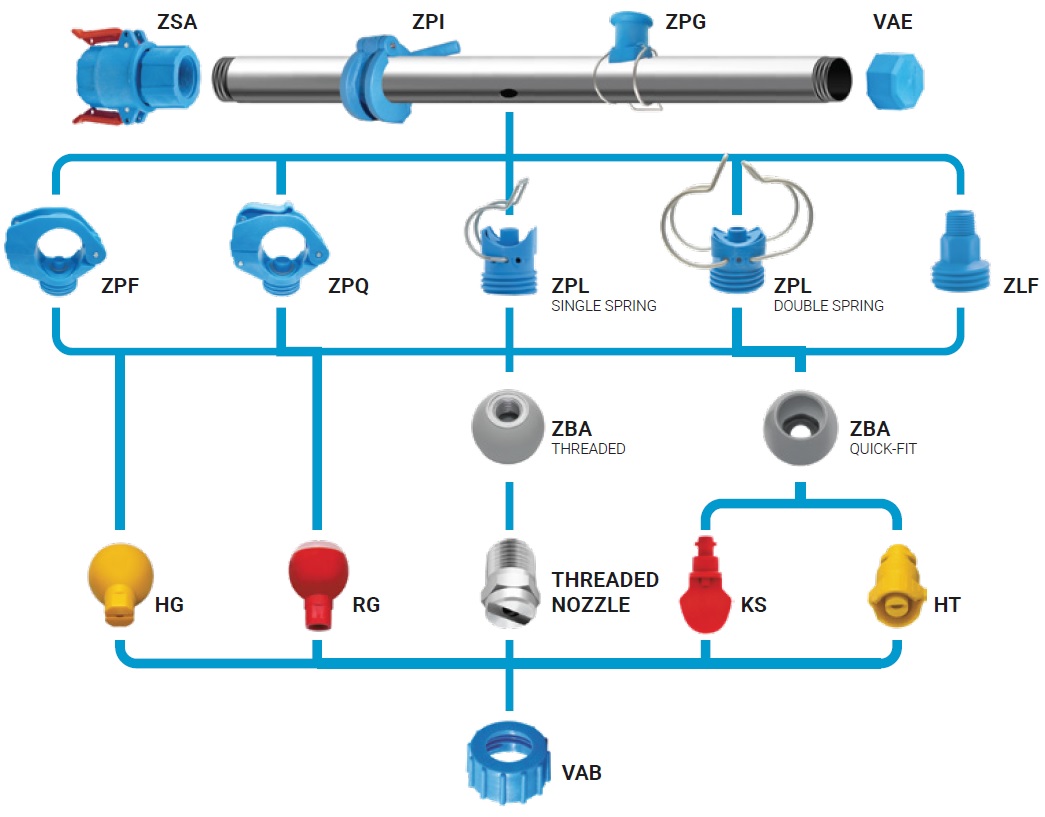

The design of the nozzles and quick coupling accessories allow for easy control and quick cleaning of the nozzles to keep the system in perfect working condition. Quick-fit spray nozzles and accessories are assembled starting from the pipe clamps by drilling a hole in the spray manifold. Depending on the application requirements, threaded or quick-connect balls, quick-connect nozzles, and locknuts are mounted to the clamps.

What are Quick Fit Spray Nozzles?

Quick fit spray nozzles and accessories are easy to assemble and disassemble devices, even without specific tools. In some cases, they swivel and are often made of plastic material. Generally, quick-fit spray nozzles are connected to the liquid supply with a clamp: in most cases, a simple hole is made in the manifold, and the spraying unit is installed (consisting, for example, of a clamp, swivel ball, nozzle, and locknut).

PIPE CLAMPS

Spray nozzle pipe clamps are articulated, cam, double or single spring and can accommodate all types of nozzles with quick coupling. To mount the pipe clamps, drill a hole in the manifold, insert the spigot and fix it. Thanks to the materials of construction, the pipe clamps are corrosion-resistant and extremely durable.

What is the difference between quick fit spray nozzles and traditional nozzles?

As the name already makes clear, the main difference between quick fit and traditional nozzles is their connection. Quick connection nozzles require a clamp to connect to the liquid supply. In contrast, conventional nozzles have several types of connections available including thread, flange, clip, or welding.

When should I use quick fit spray nozzles?

Many industrial facilities require quick-fit spray nozzles and accessories, including car wash plants, painting, phosphating and powder coating plants, food washing machinery, equipment for rinsing containers, and many others. In general, this type of product is used in industrial applications that require quick assembly and adjustment of the orientation and spray coverage of the nozzles.

What are the advantages of quick-fit nozzles and accessories?

SPEED

Quick fit spray nozzles and accessories are characterized by the speed of installation and disassembly for maintenance.

FLEXIBILITY

This type of nozzle are easily adjustable and adaptable to almost every applications requirements.

DURABILITY

The Glassfibre reinforced PP which many quick-fit spray nozzles and accessories are composed, guarantees high impact resistance, improved mechanical properties, and greater tensile strength.

Assembly Chart

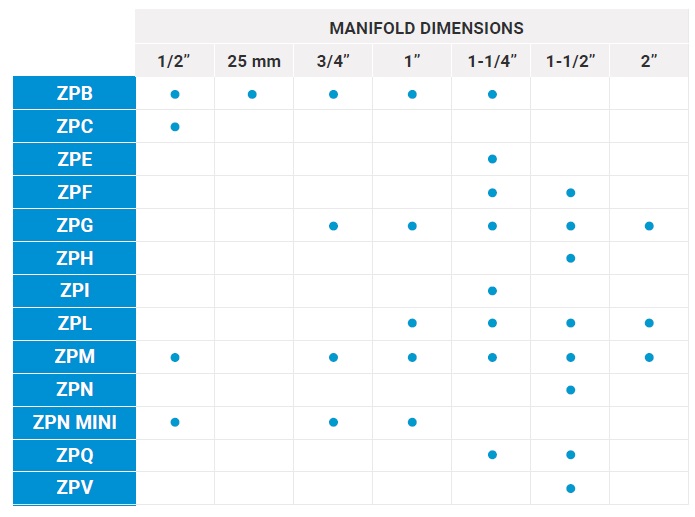

COMPATIBILITY TABLE FOR PIPE CLAMPS AND MANIFOLDS

Size of manifolds in inches/mm. The dot states that the pipe clamp can be installed on a manifold of the indicated size.