Flow Rate

N/A

Material

AISI 316L s.s

Connection

N/A

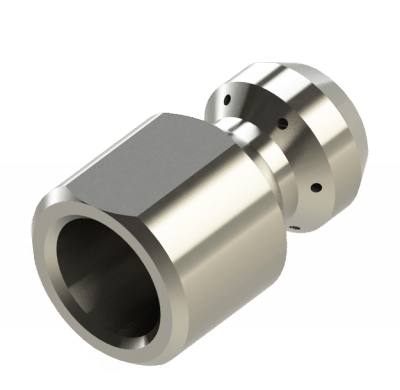

Description

The CSI Tablet Coating Nozzle Mk III has been designed and developed from the popular Mk I and Mk II nozzles, incorporating performance features associated with those nozzles. These nozzles represent cutting edge technology, striving to provide outstanding and consistent results in all tablet coating applications. They deliver effective and highly controlled film coating onto solid dosage products, the latest spray nozzle incorporates many clever design features. A series of spray manifolds have also been developed, with enhanced aerodynamic properties, to minimise air turbulence of the co-current airflow within the drum, thus reducing the risk of unwanted spray drying, with the associated inefficiencies. These factors coupled with utilising the very latest anti-bearding technology eliminates the time lost by stopping the process to clean the air caps.

| SPRAY NOZZLE SPECIFICATION | ||

| Spray Nozzle | Type | CSI Mk III |

| Spray Type | Airborne | Air Atomised |

| Spray Nozzle Liquid Tip Size Standard (Optional) | mm | 1.2 (0.8 / 1.8) |

| Solution Flow rate (Typical per nozzle) | ml/min | 50 – 150 |

| Solution Viscosity (Typical per nozzle) | MPa | 5 – 350 |

| Solution Pressure Trip Setting (optional) | bar | 2.5 |

| Atomising Air Pressure Range | bar | 1.0 – 4.0 |

| Spray Width Pressure Range | bar | 0.0 – 4.0 |

| Maximum Compressed Air Pressure | bar | 5.5 |

| Compressed Air Consumption (maximum @ 4.0 bar) | Litres/min | 120 |

Product Reviews

There are no reviews yet.