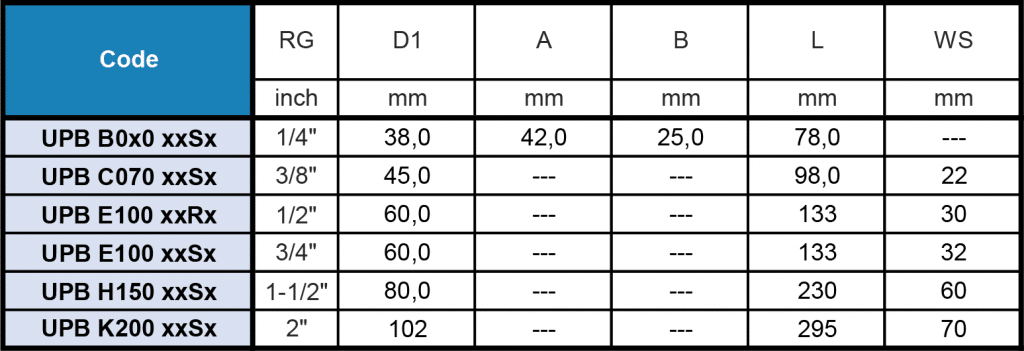

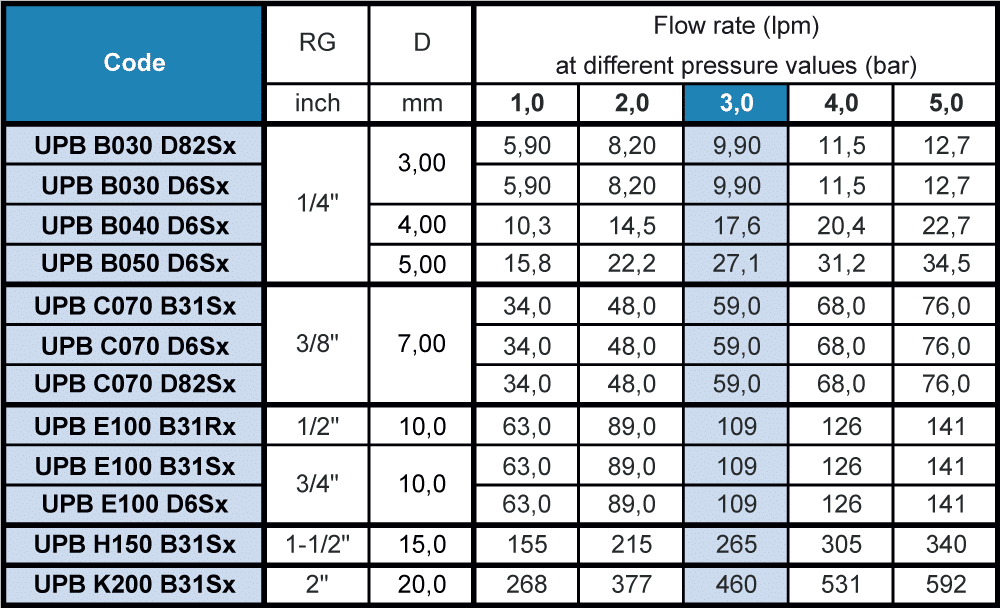

Flow Rate

lpm@3bar (59 to 357)

Material

AISI 316L s.s. PP, chemically bonded fiberglass PVDF, moulded

Connection

Male BSPT, BSPP Male NPT

From 1/4″ to 2″

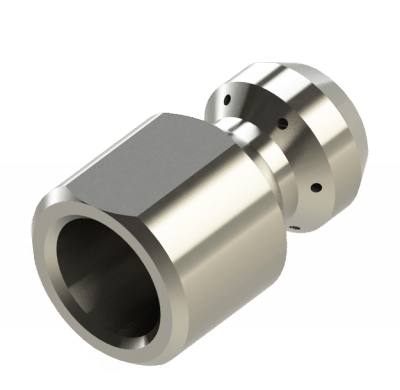

Description

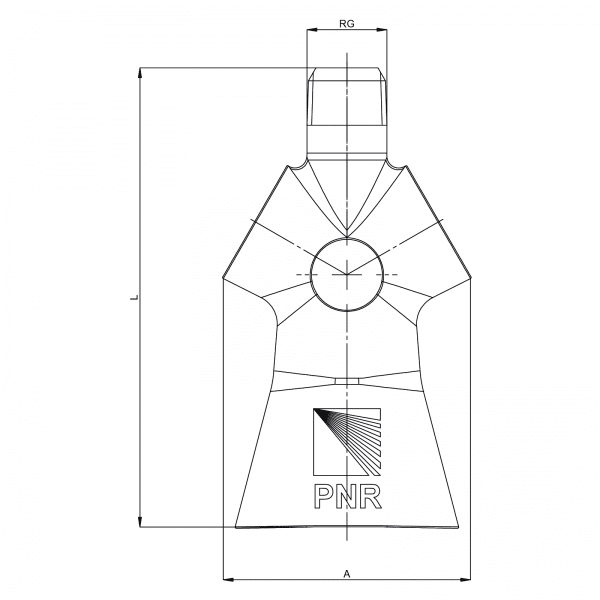

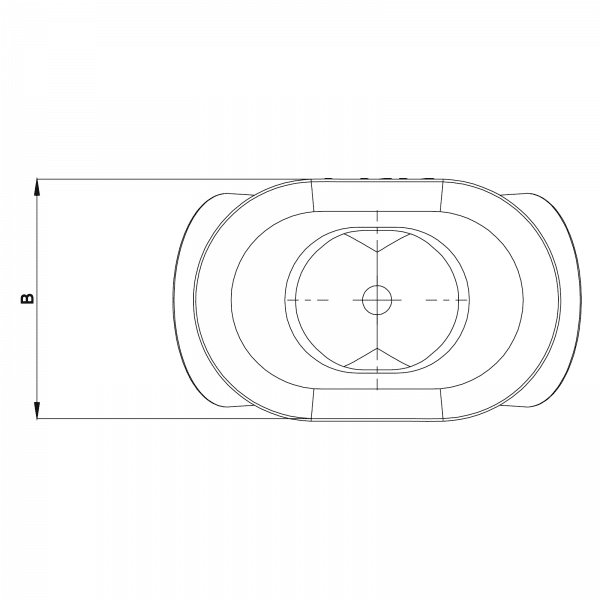

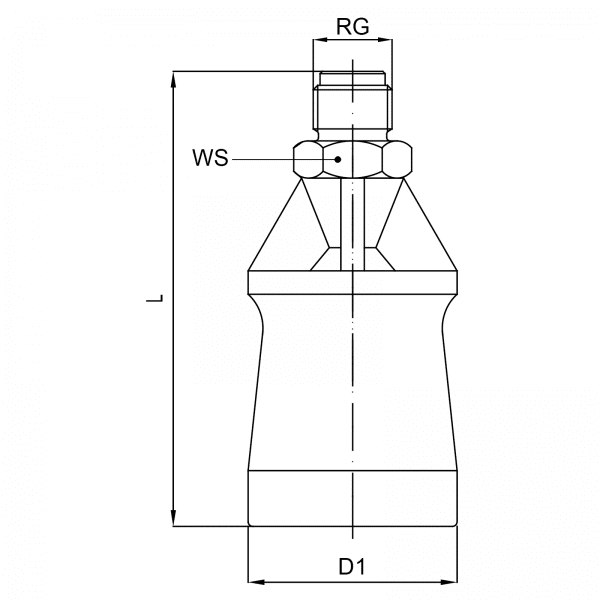

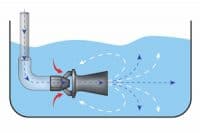

UPB – Mixing Eductors UPB mixing eductors are energy-saving products. Their robust bell-shaped body minimizes the risk of damage during maintenance operations and the Venturi design assures a high mixing efficiency. These eductors enable the circulation of large volumes of liquid and are ideal for continuous blending and stirring of liquids or solutions in tanks. The UPB eductors are installed at the bottom of a tank and pressurized to spray the solution. This flow creates a powerful negative pressure that allows to take in four times the liquid volume, mix it with a solution inside the nozzle and spray it back into the tank at a high speed.

1 HP pump and UPB mixing eductor can replace a 5 HP mixing educator. UPB eductors are an efficient way to get the best performance from re-circulating process tanks and are cost-effective because they reduce electrical costs.

Thread: 1/4″ – 2″

Capacity: 59- 357 L/min

Material: AISI 316L, PVDF, Glass filled polypropylene Now available in highly polished 316SS for ultra-hygienic applications in the food industry.

Typical applications – Liquid mixing in electroplating and automotive paint factories, steam heating and mixing of liquid food products

Product Reviews

There are no reviews yet.