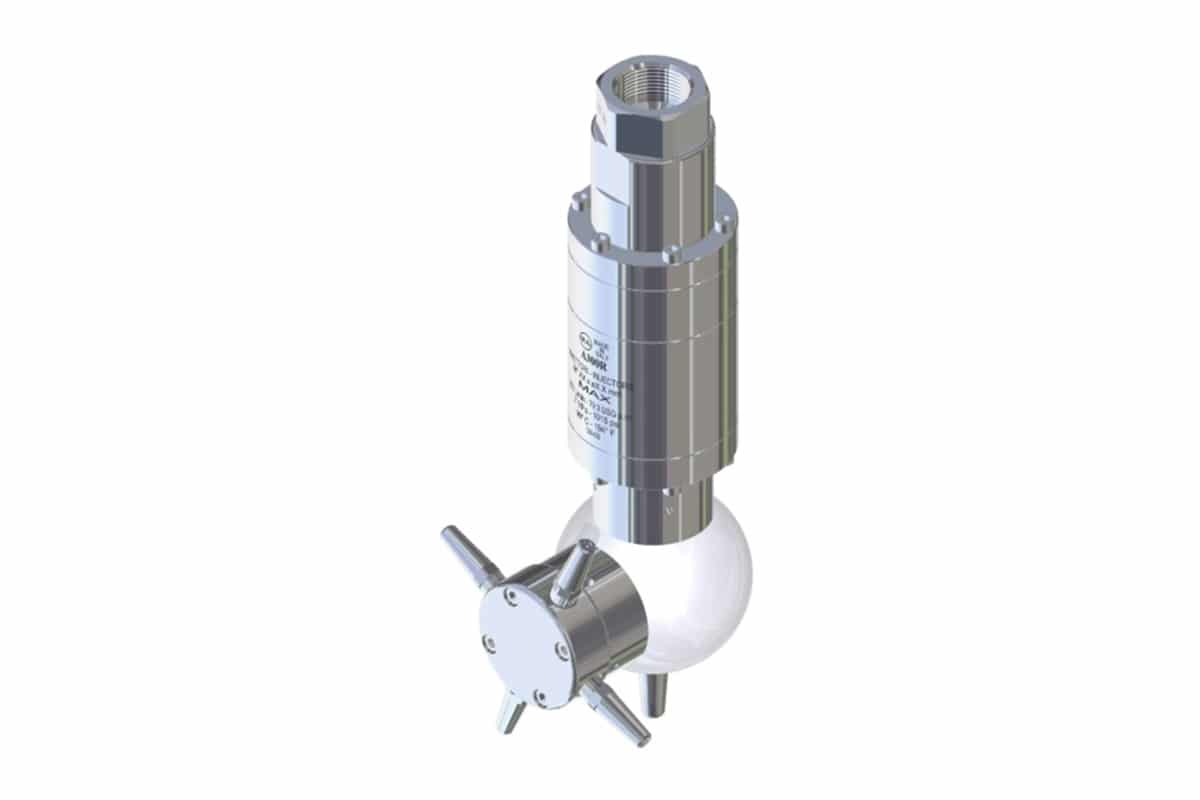

Max Cleaning Diameter

4.8m

Flow Rate Range

50 - 119 L/min

Pressure Range

1 - 4 bar

Description

Rotating Spray Cleaner Torus 100

Advantages

- Hygienic design

- Economic flow rates

- Ball bearing free-increased service life

- Low operating pressure

- FDA conform and ATEX exempt

- Versatile range of applications

- SIP through the nozzle possible

- Preferred mounting position: any

- Available for tank safety system VARITOP®

Technical Data

Recommended pressure: 1-4 bar (14.5-58 psi)

Cleaning diameter: 4.8m

Flow rate: 50-118 L/min

Spray pattern: 360° (180° on request)

Operating temp: 65°C

Ambient temp: SIP max 75°C 30 min

Insertion opening: 85mm

Materials: 316LSS with PTFE or C-PTFE (ATEX)

Connection: Pin fix for 1″ OD pipe (25.4×1.6mm)

Versatile & Unique

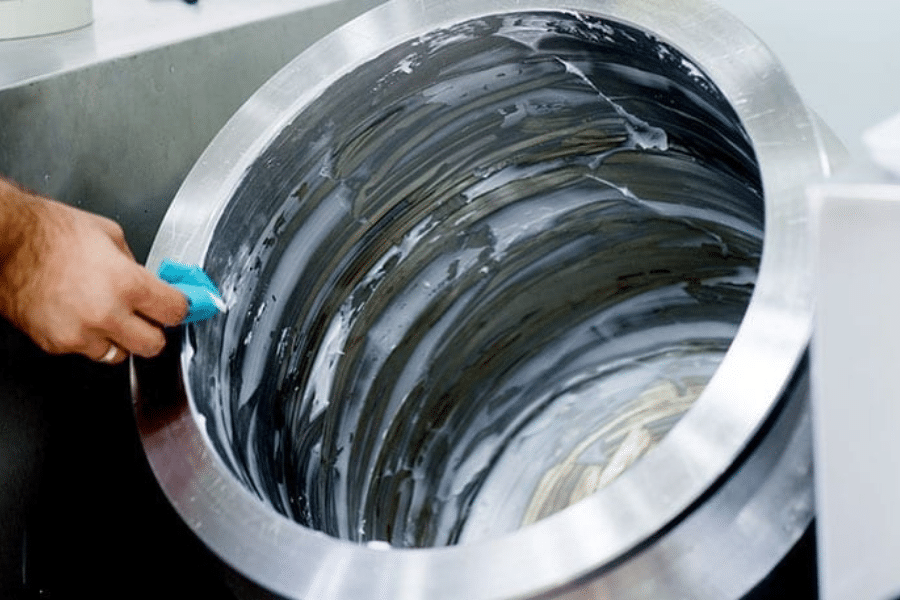

The Torus 100 has a very simple yet highly effective design. The unique design of the rotating disc of water provides instant and effective total coverage across the inside of the vessel. This action provides consistent repeatable cleaning. The single moving part provides a very low maintenance, very low cost of ownership and compact cleaning solution.

Applications

The Torus 100 is ideal for replacing fixed or rotating spray balls. The high energy, fast moving droplets provide very effective impingement up to two metres, meaning a single unit can clean vessels up to four metres in diameter. Compact in design, effective in performance, they meet all the essential FDA material requirements and are also available in ATEX exempt form. This makes the units highly suitable for the pharmaceutical, biotech, food, beverage and other hygiene conscious industries.

Operation

Wash fluid enters a drive chamber creating a disc of moving water. The wash fluid exits the unit through the small number of slots in the external disc. The specially designed pattern of slots ensures the high energy droplets use the minimum amount of wash fluid to deliver optimum performance.

Maintenance & Inspection

The low friction design requires minimal maintenance. Any spare parts, technical assistance or repair facilities required can be obtained through the global Breconcherry distributor network. As with all mechanical devices, it is recommended that the unit be regularly inspected for correct operation.

Product Reviews

There are no reviews yet.