Max Cleaning Diameter

5m

Flow Rate Range

40 - 245 L/min

Pressure Range

2 - 4 bar

Description

Rotating Spray Cleaner

Chemidisc 25 / 75 / 100 / 150

Advantages

- Economic flow rates

- Ball bearing free-increased service life

- Maintenance free

- Hydrodynamic bearing

- FDA conform and ATEX exempt

- SIP through the nozzle possible

- Preferred mounting position: any

- Chemical resistant – ideal for corrosive environments

- Lightweight construction – safer in glass lined vessels

- Effective wash – due to high rotation speed

Technical Data

Recommended pressure: 2-4 bar (29-58 psi)

Cleaning diameter: 1.5m, 3m, 4.6m and 5m max

Flow rates: 40-60 l/m, 59-83 l/m, 95-134 l/m, 163-220 l/m

Spray pattern: 360° (180° on request)

Operating temp: 95°C max

Ambient temp: SIP max 140°C 30 mins

Insertion opening: Ø31mm, Ø41mm, Ø55mm, Ø75mm

Material: C-PTFE or PTFE

Connection: 1/4″ BSPM, 3/4″ BSP, 1″ BSP, 1.5″ BSP

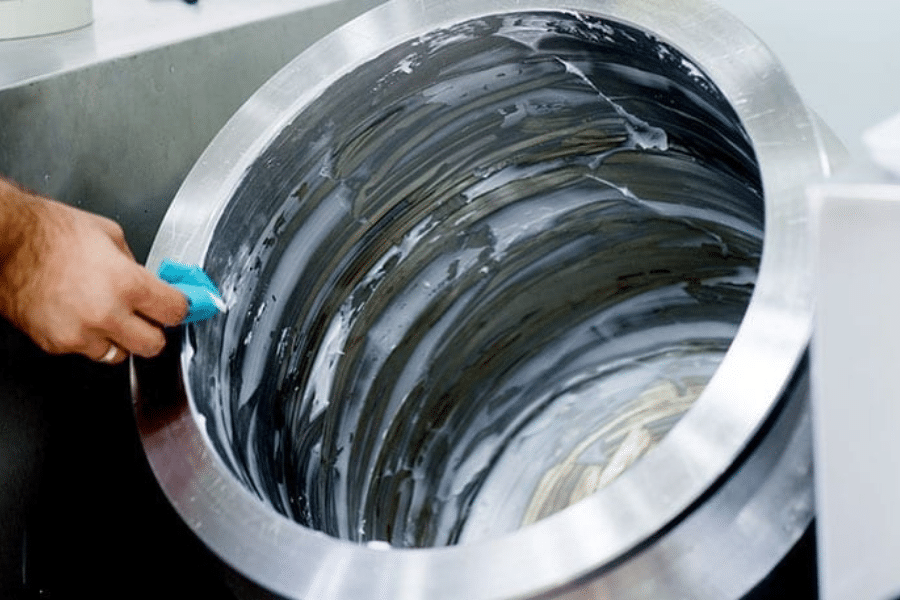

Versatile & Unique

The CHEMIDISC offers powerful low cost cleaning performance manufactured in chemical resistant materials for the pharmaceutical, chemical, nuclear, and food industries where FDA CFR21 compliance, and heightened standards of hygiene and performance are necessary. CHEMIDISC sprayheads are ideal for burst rinsing and can be placed into the tank at any angle.

Applications

The CHEMIDISC range is available in a wide variety of sizes and is designed for use in harsh chemical environments, as a Hastelloy alternative and in glass lined vessels. CHEMIDISCs constructed in carbon filled PTFE dissipate static electricity in potentially explosive atmospheres. Pure PTFE CFR21 compliant CHEMIDISCs are used in many pharmaceutical and other applications where the cleaning solution is corrosive to stainless steel. PEEK is available for nuclear and specialist applications. The CHEMIDISC cost effectiveness and reliability is specified by end users, OEMs and contract design companies.

Operation

CHEMIDISC has a unique ball bearing free design, meaning no shedding of metal bearing debris and no failure to rotate. CHEMIDISC has only one moving part, the rotating disc which rides friction free on a hydraulic bearing which instantly converts the wash fluid into a sphere of fast moving droplets, distributing the fluid in a complete and uniform manner. Total surface cover is achieved as fast moving, high power droplets simultaneously reach the entire surface of the tank, inlet pipe and overhead nozzles where contamination frequently occurs.

Product Reviews

There are no reviews yet.