Pressure Relief

Pressure Relief refers to the process or mechanism designed to release or vent excess pressure from a system, container, or equipment to prevent overpressurization. Maintaining optimal pressure levels is crucial for the safe operation of various systems and devices. Relief systems are employed in different industries to protect equipment, prevent catastrophic failures, and ensure the safety of personnel.

1. Importance of Pressure Relief:

- Safety:

- Pressure relief is vital for preventing the buildup of excessive pressure, which can lead to equipment failure, leaks, or even explosions. This is especially critical in systems that handle volatile or hazardous substances.

- Equipment Protection:

- Overpressure can damage or compromise the integrity of equipment, including vessels, pipelines, and tanks. Relief mechanisms protect these assets from potential harm.

- Process Control:

- Pressure relief plays a role in maintaining control over industrial processes by preventing pressure-related disruptions that could impact production.

2. Common Pressure Relief Devices:

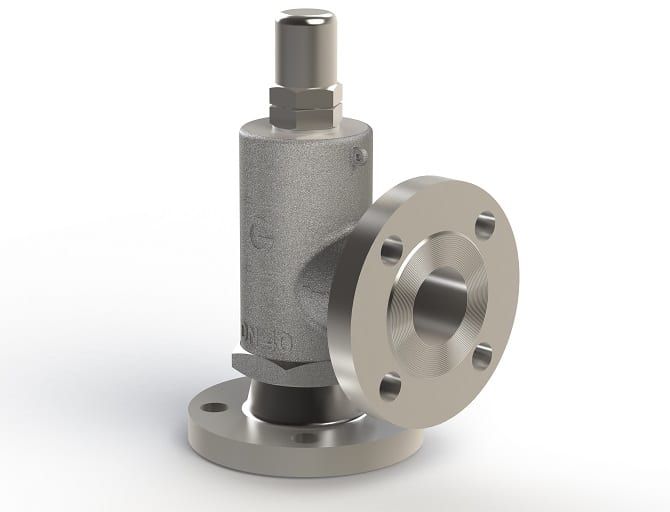

- Pressure Relief Valves (PRVs):

- PRVs are mechanical devices designed to open and relieve excess pressure when it reaches a predetermined set point. They are commonly used in various applications, including steam boilers, pressure vessels, and pipelines.

- Rupture Discs:

- Rupture discs are non-reusable, thin, and typically metal devices that burst at a predetermined pressure. They provide rapid and instantaneous pressure relief.

- Safety Relief Valves:

- Safety relief valves are similar to PRVs but are typically designed to handle larger capacities. They automatically open to release excess pressure and reseat when the pressure returns to a safe level.

- Pressure Safety Valves (PSVs):

- PSVs are a specific type of safety valve designed to protect pressure vessels, especially in the oil and gas industry. They automatically release excess pressure to prevent overpressurization.

3. Pressure Relief System Design:

- Set Points:

- The relief devices are set to open at predetermined pressure levels, known as set points. These set points are determined based on the design specifications and safety requirements of the system.

- Location:

- The placement of pressure relief devices is strategically determined to ensure effective pressure relief without compromising the safety of personnel or nearby equipment.

- Integration with Process Controls:

- Pressure relief systems are often integrated with overall process control systems. This integration ensures coordinated responses to pressure variations and enhances the overall safety of the operation.

4. Industry Standards and Regulations:

- ASME Boiler and Pressure Vessel Code:

- The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code provides guidelines and standards for the design, construction, and operation of pressure vessels and related systems.

- API Standards:

- The American Petroleum Institute (API) establishes standards for the design and operation of equipment in the oil and gas industry, including guidelines for pressure systems.

5. Testing and Maintenance:

- Regular Inspection:

- Pressure valves should undergo regular inspection to ensure they are in proper working condition.

- Testing:

- Periodic testing, such as bench testing or in-service testing, helps verify the functionality of pressure relief devices.

- Record Keeping:

- Documentation of inspection, testing, and maintenance activities is essential for compliance with industry regulations and standards.

6. Emergency Situations:

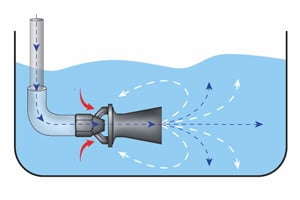

- Emergency Venting:

- In certain situations, emergency venting provisions may be included to handle extreme pressure buildup, especially in processes involving hazardous materials.

- Emergency Shutdown Systems:

- Integrated with pressure relief systems, emergency shutdown systems can initiate a rapid shutdown in the event of an emergency, preventing further pressure buildup.

Pressure relief is a critical aspect of industrial safety, ensuring the protection of personnel, equipment, and the environment. The design, implementation, and maintenance of effective safety systems are essential components of overall process safety in various industries. Compliance with industry standards and regulations is crucial to ensure the reliability and functionality.