Our experts are just a call away. Contact us now for immediate assistance and personalized solutions!

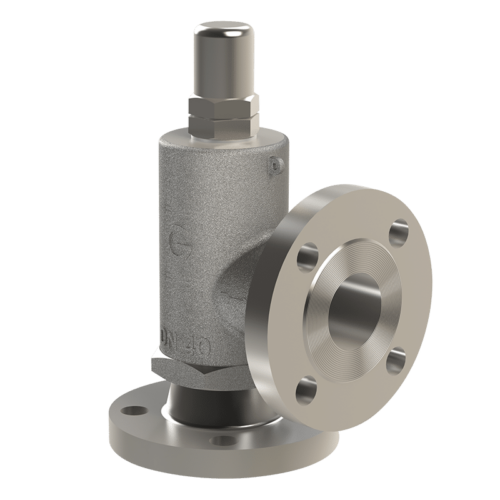

A pressure relief valve (PRV), also known as a pressure safety valve (PSV) or pressure release valve, is a crucial safety device used to protect pressure vessels, pipelines, and other systems from excessive pressure buildup. Its primary function is to prevent overpressure scenarios that could potentially lead to equipment failure, explosions, or other hazardous situations.

When the pressure within a system exceeds a predetermined set level, the pressure relief valve activates and releases excess pressure to the atmosphere or to a safer area. This prevents the pressure from exceeding safe limits and helps maintain the integrity of the equipment and the safety of personnel.

Pressure relief valves work based on the principle of balancing forces. They are typically designed with a spring mechanism that keeps the valve closed, and the force of the pressure inside the vessel opposes this spring force. When the pressure reaches a critical point, it overcomes the spring force, causing the valve to open and allow excess pressure to escape.

There are different types of pressure relief valves, including:

- Spring-loaded Pressure Relief Valve: This is the most common type of PRV. It consists of a spring-loaded disc that sits against a seat. When the pressure exceeds the set level, the spring is compressed, and the disc lifts off the seat, allowing excess pressure to be released.

- Pilot-operated Pressure Relief Valve: In this type, a smaller control valve, called a pilot valve, is used to control the opening and closing of the main relief valve. This allows for more precise pressure control and can be used for high-pressure applications.

- Rupture Disc (Bursting Disc): Instead of being spring-loaded, a rupture disc is a thin, typically circular, metal disc that bursts at a predetermined pressure. It is used in applications where very rapid and precise pressure relief is needed.

Pressure relief valves are commonly found in various industries, including oil and gas, chemical processing, power generation, manufacturing, and more. They are essential for preventing catastrophic failures due to pressure buildups, which can lead to accidents, equipment damage, and potential harm to human life. Regular maintenance and testing of pressure relief valves are crucial to ensure their proper functioning when needed.