Powder Coating Pre-treatment

Powder coating pre-treatment is a crucial step in the powder coating process to ensure proper adhesion, corrosion resistance, and overall durability of the coated surface. Pre-treatment involves the preparation of the substrate (metal or other materials) before the application of the powder coating. The goal is to clean, etch, and provide a suitable surface for the powder coating to adhere to effectively. Common pre-treatment methods for powder coating include:

1. Cleaning:

- Solvent Cleaning:

- Initial cleaning involves the removal of dirt, oil, grease, and other contaminants from the substrate. Solvent cleaning using degreasers or solvents helps achieve a clean surface.

- Alkaline Cleaning:

- Alkaline cleaning, often done in a multi-stage washer, uses alkaline solutions to remove contaminants and prepare the substrate for further treatment.

2. Surface Etching:

- Phosphating:

- Phosphating is a chemical process that involves the application of a phosphate conversion coating to the metal substrate. This coating enhances corrosion resistance and provides a bonding surface for the powder coating. Iron or zinc phosphate is commonly used.

- Chromate Conversion Coating:

- Chromate conversion coatings, such as hexavalent chromium or trivalent chromium, are applied to aluminium surfaces. These coatings improve adhesion and provide corrosion resistance.

- Titanium Zirconium Pretreatment:

- An eco-friendly alternative to traditional phosphating, this process involves the application of titanium zirconium conversion coatings, offering excellent adhesion and corrosion resistance.

3. Surface Conditioning:

- Abrasive Cleaning:

- Part of powder coating pre-treament includes sanding, blasting, or abrasive cleaning can be used to create a slightly roughened surface, improving the mechanical adhesion of the powder coating.

4. Rinsing:

- Water Rinsing:

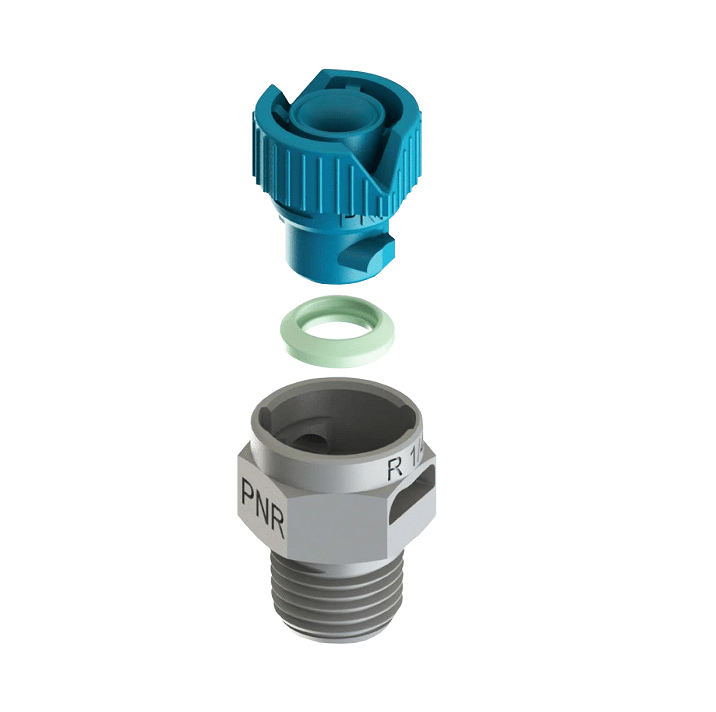

- After cleaning and treatment processes, rinsing with water nozzles removes residual chemicals and ensures that the substrate is ready for the application of the powder coating.

5. Drying:

- Air Drying or Forced Drying:

- The substrate must be thoroughly dried to eliminate any moisture before the powder coating is applied. Air drying or forced drying methods are used depending on the specific requirements.

6. Masking:

- Masking Off Areas:

- Masking involves covering specific areas of the substrate that should not be coated. It is often done using tapes or other masking materials to protect certain features or parts from receiving the powder coating.

7. Application of Powder Coating:

- Electrostatic Application:

- Powder coating is applied to the pre-treated substrate using an electrostatic spray gun. The charged powder particles adhere to the grounded substrate, creating a uniform coating.

8. Curing:

- Oven Curing:

- The coated substrate is then cured in an oven, where the powder particles melt and fuse to form a smooth and durable finish.

Proper powder coating pre-treatment is critical for achieving high-quality and long-lasting finishes. The specific pre-treatment method depends on factors such as the substrate material, the desired coating properties, and environmental considerations. Following industry standards and best practices ensures that the powder coating adheres effectively and provides the intended protection and aesthetics.

Founded in 1982, Tecpro Australia has developed an enviable reputation for providing reliable and cost-effective technical solutions for a vast range of industrial applications. Products suitable for powder coating pre-treatment application include:

* Spray Nozzles

Our customers benefit from the following:

• Access to a broad range of quality solutions and technical advice

• Local sales support and customer service with a focus on integrity and honesty

• Over 30 years’ experience of providing expertise and solutions

• Quality European manufactured products.