Parts Washing

Parts washing is a process used to clean and remove contaminants, such as grease, oil, dirt, and other residues, from various types of components or parts. This cleaning method is widely employed in manufacturing, automotive, aerospace, and other industries where maintaining the cleanliness of components is crucial for quality, safety, and performance. Parts washing can be carried out using various techniques and equipment. Here are key aspects of parts washing:

1. Purpose of Parts Washing:

- Contaminant Removal:

- The primary purpose of parts washing is to remove contaminants such as oil, grease, metal shavings, dirt, and other residues from the surfaces of components.

- Preparation for Assembly or Processing:

- Clean parts are essential for assembly, further processing, or finishing operations. Parts washing ensures that components are free of contaminants before the next manufacturing step.

- Maintenance and Repair:

- Parts washing is often used during maintenance and repair activities to clean and prepare components for inspection, repair, or replacement.

- Quality Control:

- Clean parts are critical for maintaining quality standards in manufacturing. Parts washing helps prevent defects and ensures that products meet specified requirements.

2. Methods of Parts Washing:

- Solvent Cleaning:

- Solvent-based parts washers use chemical solvents to dissolve and remove contaminants from parts. Common solvents include mineral spirits, hydrocarbons, or water-based solutions.

- Aqueous Cleaning:

- Aqueous parts washers use water-based solutions along with detergents, surfactants, and sometimes heat to clean parts. This method is considered more environmentally friendly compared to solvent cleaning.

- Ultrasonic Cleaning:

- Ultrasonic parts washers use high-frequency sound waves to create cavitation bubbles in a cleaning solution. The implosion of these bubbles produces microscopic shockwaves that remove contaminants from the surfaces of parts.

- Vapor Degreasing:

- Vapor degreasing involves using vaporized solvents to clean parts. The vapour condenses on the parts, dissolves contaminants, and then drains away.

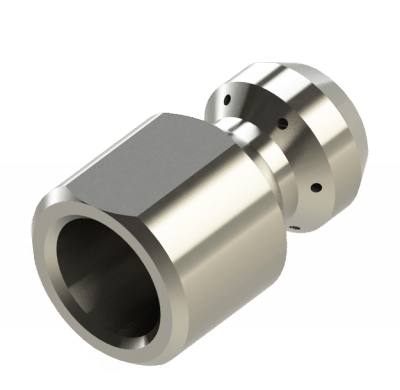

- Pressure Washing:

- High-pressure washing systems use nozzles and pressurized water or water-based solutions to remove contaminants from parts. This method is effective for cleaning larger and more robust components.

3. Equipment Used in Parts Washing:

- Parts Washers:

- Parts washers are machines specifically designed for cleaning components. They may be manual, semi-automatic, or fully automated, depending on the volume and complexity of the parts to be cleaned.

- Ultrasonic Cleaners:

- Ultrasonic cleaners use ultrasonic waves to clean parts placed in a cleaning solution. These are often used for small or intricate components.

- Vapor Degreasers:

- Vapour degreasers consist of a vapour zone and a liquid zone where parts are cleaned using vaporized solvents.

- Pressure Washers:

- Pressure washers use high-pressure water jets to clean parts. They are suitable for large and heavy components.

4. Considerations for Parts Washing:

- Material Compatibility:

- The choice of cleaning method and solution should be compatible with the materials of the parts being cleaned to avoid damage.

- Environmental Impact:

- Consideration for environmental regulations and sustainability is important, especially when choosing solvents or chemicals for parts washing.

- Safety Measures:

- Safety protocols must be followed to ensure the protection of workers involved in parts washing, especially when using solvents or other potentially hazardous substances.

- Efficiency and Throughput:

- Depending on the production volume, the efficiency and throughput of the parts washing process are crucial factors. Automation can enhance efficiency in high-volume manufacturing environments.

- Quality Control:

- Regular inspection and quality control measures ensure that the parts washing process effectively removes contaminants and meets cleanliness standards.

Parts washing is an essential step in various manufacturing and maintenance processes, contributing to the overall quality and performance of the final products. The choice of parts washing method and equipment depends on the specific requirements of the industry, the type of components being cleaned, and environmental considerations.

Founded in 1982, Tecpro Australia has developed an enviable reputation for providing reliable and cost-effective technical solutions for a vast range of industrial applications.

* Spray Nozzles

* CIP Tank Cleaning

Our customers benefit from the following:

• Access to a broad range of quality solutions and technical advice

• Local sales support and customer service with a focus on integrity and honesty

• Over 30 years’ experience of providing expertise and solutions

• Quality European manufactured products.