Gas Cooling / Gas Quenching

Gas cooling refers to the process of lowering the temperature of a gas, typically by transferring heat away from it. This process is commonly employed in various industrial, scientific, and environmental applications. Gas cooling can have several purposes, including condensation of vapour, temperature control in industrial processes, and enhancing the efficiency of certain systems.

1. Applications of Gas Cooling:

- Power Plants:

- In power generation, gas cooling is often employed to lower the temperature of exhaust gases from combustion processes. This can improve the efficiency of power plants and reduce environmental emissions.

- Industrial Processes:

- Various manufacturing and industrial processes generate hot gases that need to be cooled for process optimization and equipment protection.

- Chemical Processing:

- Gas cooling is used in chemical plants to control temperatures during different chemical reactions and to facilitate the condensation of certain substances.

- Environmental Control:

- Certain environmental control systems use gas cooling to remove pollutants or to manage the temperature of gases released into the atmosphere.

2. Methods of Gas Cooling:

- Heat Exchangers:

- Heat exchangers are commonly used for cooling. These devices transfer heat between the hot gas and a cooling medium, such as air, water, or another fluid.

- Direct Contact Cooling:

- In some cases, gas cooling involves direct contact with a cooling medium. For example, water may be sprayed directly onto hot gases to lower their temperature.

- Evaporative Cooling:

- Evaporative cooling involves the evaporation of a liquid (such as water) into the hot gas stream, absorbing heat and reducing the gas temperature.

- Refrigeration and Cryogenic Cooling:

- Gas cooling can also be achieved through refrigeration or cryogenic methods, where gases are cooled to extremely low temperatures.

3. Cooling Technologies:

- Cooling Towers:

- Commonly used in power plants and industrial facilities, cooling towers facilitate the transfer of heat from hot gases to the atmosphere through the evaporation of water.

- Chillers:

- Chillers are devices that use refrigeration cycles to cool gases or liquids for air conditioning, industrial processes, or other applications.

- Condensers:

- Condensers are heat exchangers that facilitate the phase change of a gas into a liquid by removing heat. They are often used in power plants and refrigeration systems.

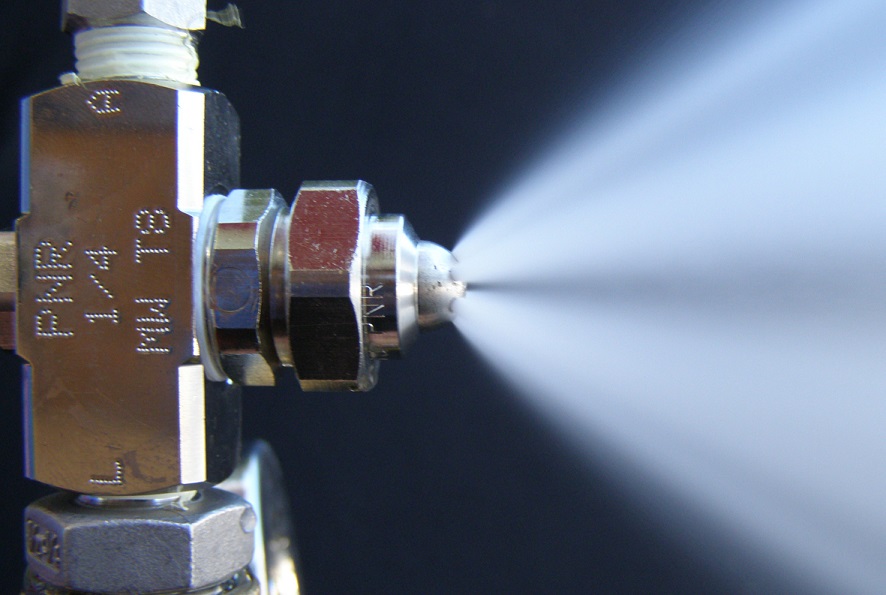

- Spray Cooling:

- Spray cooling involves the use of atomized liquid sprays to cool hot gases. This method is often used in combustion processes and industrial applications.

4. Benefits of Gas Cooling:

- Improved Efficiency:

- Gas cooling can enhance the efficiency of various processes, especially in power generation and industrial applications.

- Equipment Protection:

- Controlling the temperature of gases is crucial for protecting equipment from overheating and maintaining optimal operating conditions.

- Emission Reduction:

- Gas cooling can contribute to reducing emissions by gas scrubbing and optimizing combustion processes and ensuring effective pollutant control.

- Process Optimization:

- Many industrial processes require specific temperature conditions for optimal performance, and cooling helps achieve and maintain these conditions.

Gas cooling is a versatile process with wide-ranging applications in different industries. The specific methods and technologies employed depend on the requirements of the application, the characteristics of the gas being cooled, and the overall objectives of the process.

Founded in 1982, Tecpro Australia has developed an enviable reputation for providing reliable and cost-effective technical solutions for a vast range of industrial applications.

* Spray Nozzles

* Hose Guns & Foaming Units

* Hose Reels

* Misting Systems

* Dust Controllers

Our customers benefit from the following:

• Access to a broad range of quality solutions and technical advice

• Local sales support and customer service with a focus on integrity and honesty

• Over 30 years’ experience of providing expertise and solutions

• Quality European manufactured products.