Atomising spray nozzles efficiently cooling metals during continuous casting

Cooling Metal – Continuous casting has been around since the 1950s and is used to provide low cost/high quality production of steel, aluminium and copper before rolling in finishing mills.

An important part of the continuous casting process is cooling metal by spraying it with atomised water as it travels between the rollers. However, the clearance between the rollers is often small – rendering conventional block air atomising spray nozzles unsuitable and inefficient.

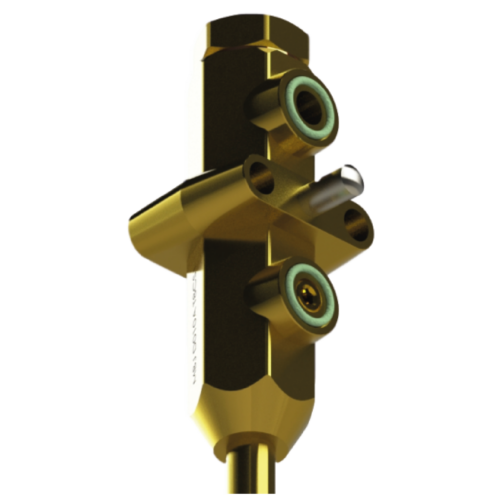

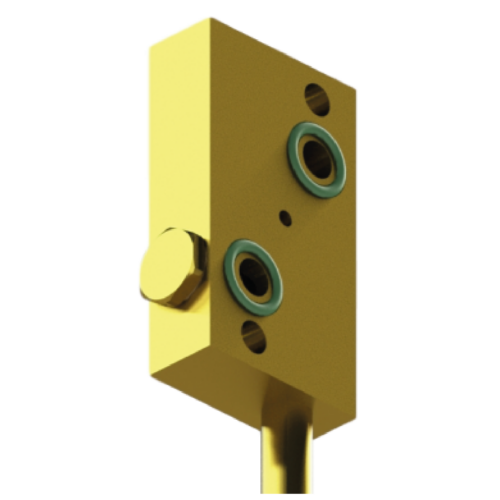

To solve this issue, PNR Italia have developed Lance Atomising spray nozzles which are specifically designed for efficiently cooling metals during the continuous casting process.

The PNR Lance Atomising spray nozzles are unique in 3 ways:

- The spray tip is located at the end of an extension pipe which can be straight or bent to shape. The extension pipes are mounted wherever required providing even greater flexibility.

- The spray nozzles are connected to compressed air as well as water. This combination creates finer water droplets to cover more surface area for increased cooling efficiency.

- The extension pipe can either be welded onto the block body or attached with a locknut.

In Australia and New Zealand, PNR Lance Atomising spray nozzles for cooling metal are only available from Tecpro Australia. With a team of engineering supply specialists, we are able to advise you on the right spray nozzle for your application.

For more information or to see Tecpro’s entire range of spray nozzles, contact us today!