Felt Cleaning

Felt cleaning is a process commonly used in industrial applications, particularly in the papermaking industry. Felt cleaning is essential for maintaining the efficiency of papermaking machinery and ensuring the quality of the paper produced. Felt fabrics in paper machines can accumulate contaminants, such as pulp fibres, chemicals, and other residues during the papermaking process. Cleaning these felts is crucial to prevent operational issues and maintain product quality. Spray nozzles play a key role in this process by delivering pressurized water or cleaning solutions to effectively remove contaminants from the felts.

1. Importance of Felt Cleaning:

- Operational Efficiency: Over time, felts in papermaking machines can accumulate debris and contaminants, affecting their ability to facilitate proper water drainage and paper formation. Regular cleaning is essential to maintain the efficiency of the papermaking process.

- Product Quality: Contaminated felts can lead to defects in the paper, affecting its quality and appearance. Felt cleaning helps ensure consistent and high-quality paper production.

- Extended Felt Lifespan: Proper cleaning contributes to the longevity of felts by preventing the buildup of materials that could lead to wear and tear.

2. Spray Nozzles in Felt Cleaning:

- Cleaning Solutions: Spray nozzles are used to deliver cleaning solutions, which may include water, chemicals, or a combination of both, to the felts. The choice of cleaning solution depends on the type of contaminants to be removed.

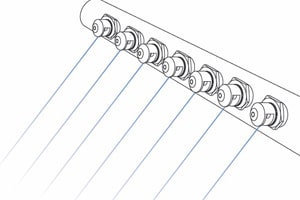

- Pressurized Spray: The spray nozzles generate a pressurized spray that effectively dislodges and removes contaminants from the felts. The force and pattern of the spray are designed to optimize cleaning efficiency.

- Uniform Coverage: Properly designed spray nozzles ensure uniform coverage of the felt surface, leaving no untreated areas. This helps achieve thorough and consistent cleaning results.

3. Types of Spray Nozzles Used:

- Flat Fan Nozzles: These nozzles produce a flat, wide spray pattern, making them suitable for covering larger areas of the felt surface. They are commonly used for initial rinsing and removal of loose contaminants.

- Needle Jet Nozzles: Needle jet nozzles produce a concentrated, high-impact spray, which is effective for targeted cleaning of specific areas on the felts that may require more intense cleaning.

- Rotating Nozzles: Some systems use rotating nozzles or oscillating devices to ensure even coverage and dynamic cleaning action across the felt surface.

4. Automated Felt Cleaning Systems:

- Integrated Systems: Many papermaking machines are equipped with automated felt cleaning systems that incorporate spray nozzles. These systems are often programmable, allowing for scheduled cleaning cycles based on machine operating conditions.

- Sensors and Monitoring: Advanced systems may include sensors to monitor the cleanliness of the felts and adjust the cleaning parameters accordingly. This helps optimize the cleaning process and reduce water and energy consumption.

5. Considerations in Felt Cleaning with Spray Nozzles:

- Contaminant Analysis: Understanding the type and composition of contaminants on the felts is crucial for selecting the appropriate cleaning solution and adjusting the cleaning parameters.

- Water Quality: The quality of the water used for felt cleaning is important to prevent nozzle clogging and maintain the effectiveness of the cleaning process.

- Nozzle Maintenance: Regular inspection and maintenance of spray nozzles are essential to ensure they are functioning properly and delivering the intended spray pattern.

Felt cleaning with spray nozzles is a vital aspect of maintaining the efficiency and quality of the papermaking process. The use of well-designed spray nozzles in automated cleaning systems helps achieve thorough and consistent cleaning of felts, contributing to the overall success of paper production.

Founded in 1982, Tecpro Australia has developed an enviable reputation for providing reliable and cost-effective technical solutions for a vast range of industrial applications. Products suitable for paper industry applications include:

* Felt Cleaning Spray Nozzles

Our customers benefit from the following:

• Access to a broad range of quality solutions and technical advice

• Local sales support and customer service with a focus on integrity and honesty

• Over 30 years’ experience of providing expertise and solutions

• Quality European manufactured products.