Max Cleaning Diameter

3.2m

Flow Rate Range

4 - 300 L/min

Pressure Range

1.5 - 3 bar

Description

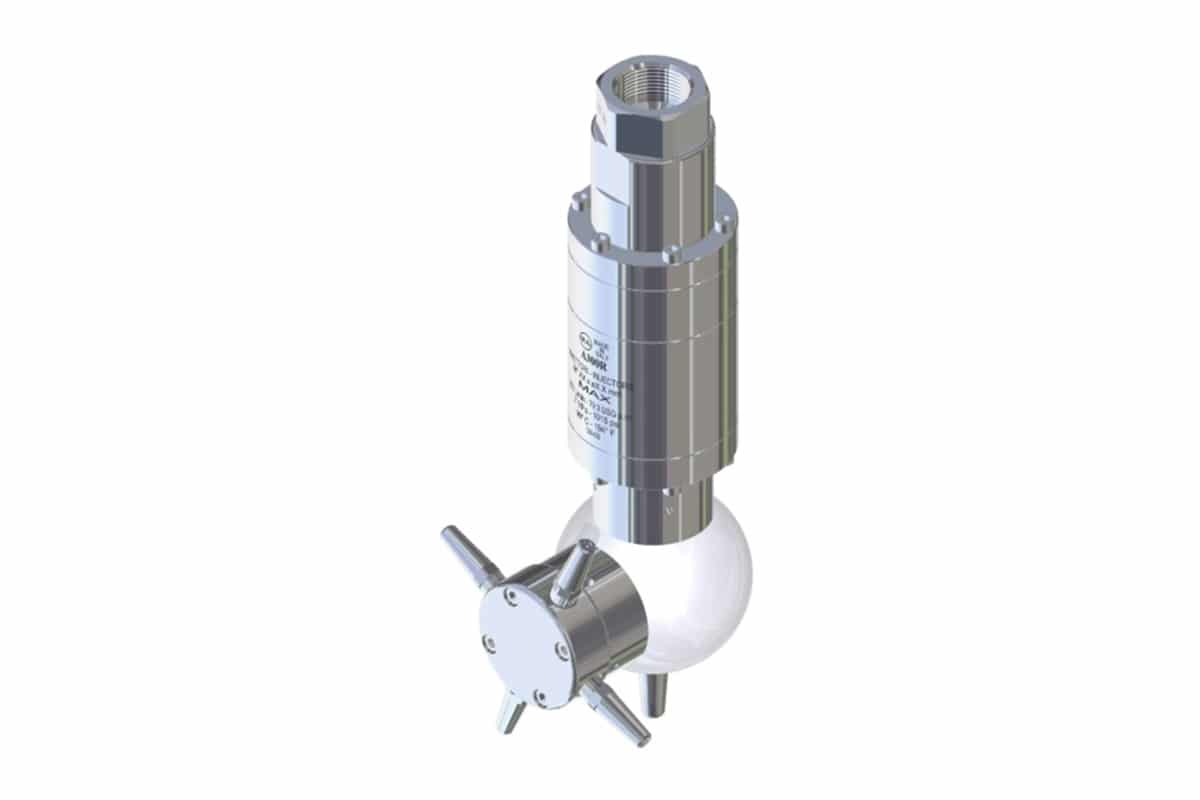

Spate cleaner TANKO-S

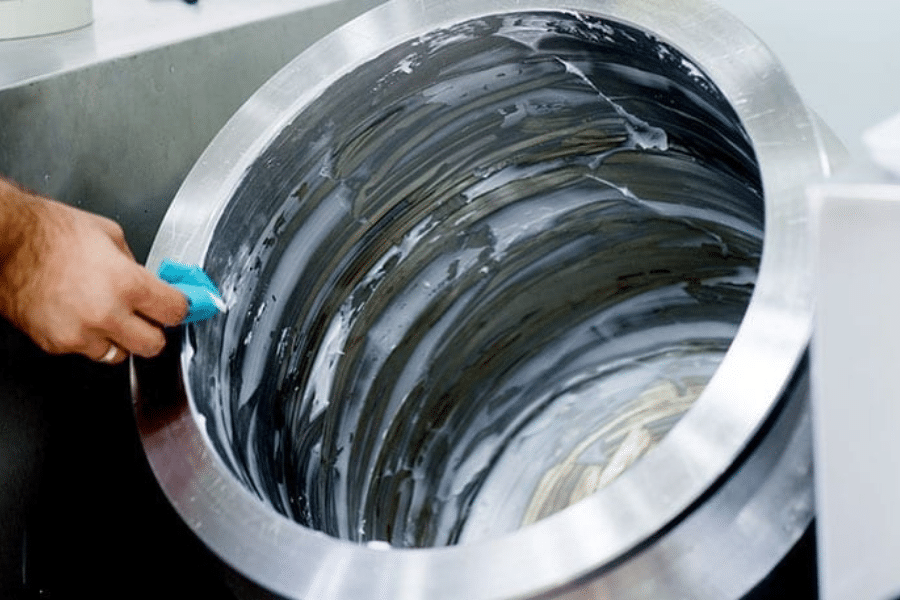

Cleaning devices for tanks or vessels are being applied since several decades. The achievable cleaning results could be considerably improved by developing new devices. Thanks to AWH development work, significant savings, best cleaning results and product safety emerge from today€™s economical spate cleaners (TANKO-S).

With the new construction AWH waives a thread.

For the €œweld-on version€ the customer receives a thread-free device. The spray head is firmly attached to the base plate, which is welded to the downpipe as a whole. This construction has increased the hygienic optimization of the TANKO-S to a maximum degree. For best assembly into the vessel, the TANKO-S is optimally supplemented by the AWH downpipe concept.

| Material | 316L (1.4435), 316L (1.4404), HC22 (2.4602), HC4 (2.4610) |

| Pressure | 1.5 – 3 bar / 21.8 – 43.5 psi * |

| Volume flow rate |

0.25 – 18 m³/h / 4.2 – 300 l/min / 1 – 79 gpm (US) * |

| Cleaning radius | 0.1 – 3.2 m / 0.3 – 10.5 ft * |

| Wetting radius | 0.1 – 4.2 m / 0.3 – 13.8 ft * |

| Connection |

Clipon Thread Orbital weldon acc. DIN 11866 |

| Bearing | Spray ball supported in double bearings |

*depending on model and cleansing medium

A Case Study of TANKO-S50

“The AWH TANKO-S50 reveales his saving potential in practice at one of the largest German breweries.”

One of the most renowned German breweries applies the TANKO-S50 for cleaning their fermentation tanks with great success. After extensive tests all 76 tanks were equipped with the TANKO-S50 in 2010. They have a capacity of 700 m³ and dimensions of up to 25 m height and 6 m width. The customer is highly satisfied with the newest TANKO-S50, which is economical and durable. At the same time the TANKO-S50 offers a significantly better cleansing effect and manufacturing quality compared to the previous static spray heads. The customer gladly provides his experiences regarding the achieved savings from the introduction of the TANKO-S50:

Savings from the TANKO-S50

• 34 % reduced CIP time

• 58 % fresh water consumption

• 39 % consumption of lye

• 11 % consumption of acid

• 58 % less waste water

The customer is highly convinced of the economic efficiency of the TANKO-S50 and has recommended the TANKO-S50 to further.

| Static Spray Head | TANKO-S50 | Differences | |

| Time (min) | 108 | 73.75 | -34.25 |

| Flow rate (m3/h) | 60 | 22 | -38 |

| Costs (‚¬) | |||

| Fresh water | 33,15 ‚¬ | 10,66 ‚¬ | -22,49 ‚¬ |

| Lye | 14,13 ‚¬ | 8,48 ‚¬ | -5,65 ‚¬ |

| Acid | 3,95 ‚¬ | 3,56 ‚¬ | -0,40 ‚¬ |

| Disinfection agents | 0,00 ‚¬ | 0,00 ‚¬ | 0,00 ‚¬ |

| Waste water | 34,00 ‚¬ | 10,93 ‚¬ | -23,07 ‚¬ |

| 85,23 ‚¬ | 33,62 ‚¬ | -51,60 ‚¬ per cleaning cycle | |

| Savings | 61 % |