About Tecpro Australia

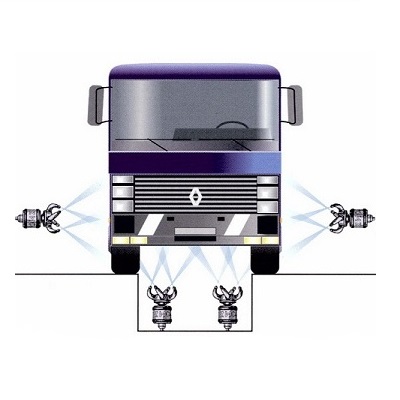

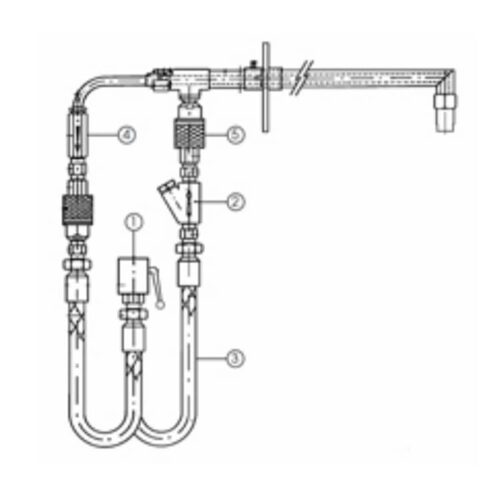

Tecpro Australia are the spray nozzle specialists who offers technical advice and supply of spray nozzles, CIP tank cleaning equipment, wash down guns, hose reels and hose, filter nozzles, fog nozzles, dust control cannons and misting systems for dust suppression or evaporative cooling as well as a range of disinfection equipment.

Product Categories

Applications

Latest News

New HAI Series Hose Reels – Durability and Aesthetic Appeal

Ramex, Italian hose reel manufacturer renowned for its commitment to excellence and innovation, proudly unveils its latest offering: the [...]

CURTpro – The Intelligent Dust Management Software System

Tecpro Australia is the official distributor in Australia for the all-new and updated EmiControls, CURTpro; a state-of-the-art automatic dust [...]

Hygienic Butterfly Valves from Tecpro Australia

Tecpro Australia now supplies top of the line AWH hygienic butterfly valves, spares and accessories to our customers in [...]

Testimonials

“Denis, thanks very much for the professional and thoughtful service today when choosing the atomiser nozzle. The time you took and the help in showing me the various options and spray patterns was such a welcome surprise in a world where, for a small sale, people are no where near as generous with their time as you.”

“The fuel hose reels are excellent, easy to use by all of our staff, neat and tidy, professional. I would recommend them to anyone.”

“We have been using our Hot water pressure system for around a month now, I can’t remember how we managed before we had it. It performs exceptionally well. Very quick to cover anything and everything in our detergent. It is particularly helpful on our Slicer where it enables us to wash all those hard to reach places with little effort. Such a great investment, makes all of our lives monumentally easy. Plus it also helps that Tecpro has been a pleasure to deal with”

“Denis & Graeme – Gents, just a quick thank you for your efforts on Sunday. Opening up your office and delivering the nozzles to us helped get production through the weekend. While these events are, hopefully very rare, it’s good to know that we have partners like Tecpro who are willing to assist. Again, thank you very much!”

“I thought I’d take this quick opportunity to extend my thanks to you and the Tecpro team for being extremely professional, prompt and helpful with our enquiry. As I’m sure you know, its busy times and everyone is running around trying to get things done and to schedule.”