Max Cleaning Diameter

N/A

Flow Rate Range

N/A

Pressure Range

N/A

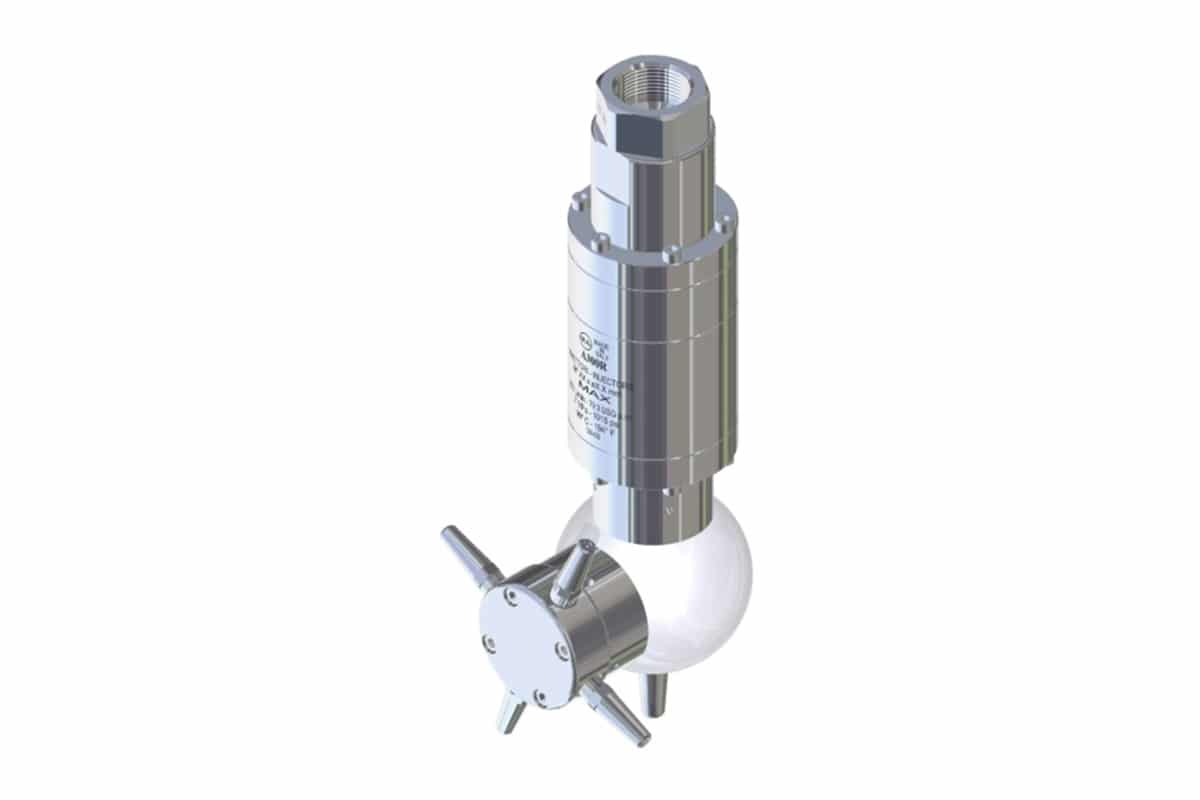

Description

Application

CIP Filters have a wide range of applications in the food-processing, cosmetics and some chemical industries as well as in auxiliary services of the pharmaceutical industry.

They have a hygienic design and are used to filter particles capable of damaging pumps and other equipment.

Operating principle

The filter basically consists of a filter body with an inlet and an outlet for the product.

The screen is fixed inside the body. The screen retains all particles that are equal or larger than the size of the screen openings.

Design and features

There are several configurations:

– Cleaning of the screen without disassembling the CIP filter:

Angular filter (82700): the inlet and the outlet form a right angle.

Y filter (83700): the product enters and leaves the filter in the same direction.

– Cleaning of the screen disassembling the filter:

Straight filter (81700): the product enters and leaves the filter in the same direction.

Low pressure drops.

DIN 11850 standard connections.

Screen with circular (from 0,5 mm to 3 mm) or longitudinal openings (10 x 1 mm).

Options

Gaskets in NBR, MVQ, FMP.

Connections: DIN, Clamp, SMS, RJT, FIL-IDF, etc.

Wedge wire screen cylinder.

Heating jacket.

Option of filtering from outside to inside of the screen.

Double filter.

Materials

Filter body: AISI316L

Gaskets: EPDM (according to FDA 117.2600)

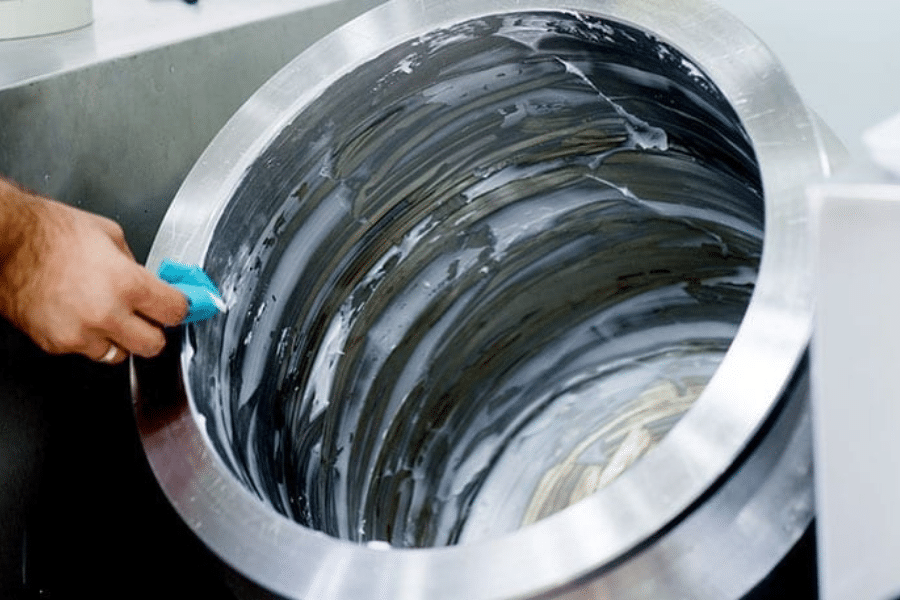

Internal surface finish: Ra < 0,8µm

External surface finish: mirror polish