Conveyor Washing & Screen Washing

Conveyor washing refers to a process in which conveyors, typically used for material handling in various industries, are cleaned and maintained to ensure optimal performance and hygiene. Conveyors are widely employed in manufacturing, food processing, packaging, and other industries to move materials from one point to another efficiently. Over time, conveyors can accumulate debris, contaminants, and residues, necessitating regular cleaning to maintain operational efficiency and meet hygiene standards. Here’s an overview of conveyor washing:

1. Purpose of Conveyor Washing:

- Hygiene and Sanitation: In industries like food processing and pharmaceuticals, maintaining a clean and sanitary production environment is crucial. Conveyor washing helps remove accumulated contaminants and prevents cross-contamination, ensuring compliance with hygiene and safety regulations.

- Operational Efficiency: Clean conveyors operate more efficiently. The removal of debris, residues, and build-ups prevents mechanical issues, reduces wear and tear, and ensures smooth material flow, leading to improved overall system performance.

- Product Quality: In industries where cleanliness is critical to product quality, such as in the production of electronics or precision components, conveyor washing helps prevent product contamination and ensures the integrity of the final output.

2. Methods of Conveyor Washing:

- Manual Cleaning: This involves workers manually scrubbing, wiping, or hosing down the conveyor components. While this method can be effective, it is labor-intensive and may not be suitable for large or complex conveyor systems.

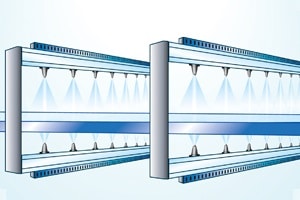

- Automated Washing Systems: Conveyor washing systems can be integrated into production lines to automate the cleaning process. These systems may include high-pressure water jets, brushes, and cleaning agents to remove contaminants efficiently.

- Dry Ice Blasting: In some industries, dry ice blasting may be used for conveyor cleaning. This method involves propelling dry ice pellets at high speeds to remove contaminants without introducing water into the system.

3. Equipment Used in Conveyor Washing:

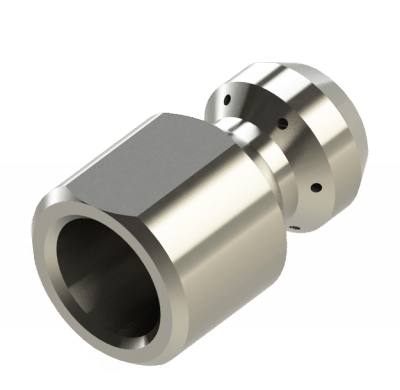

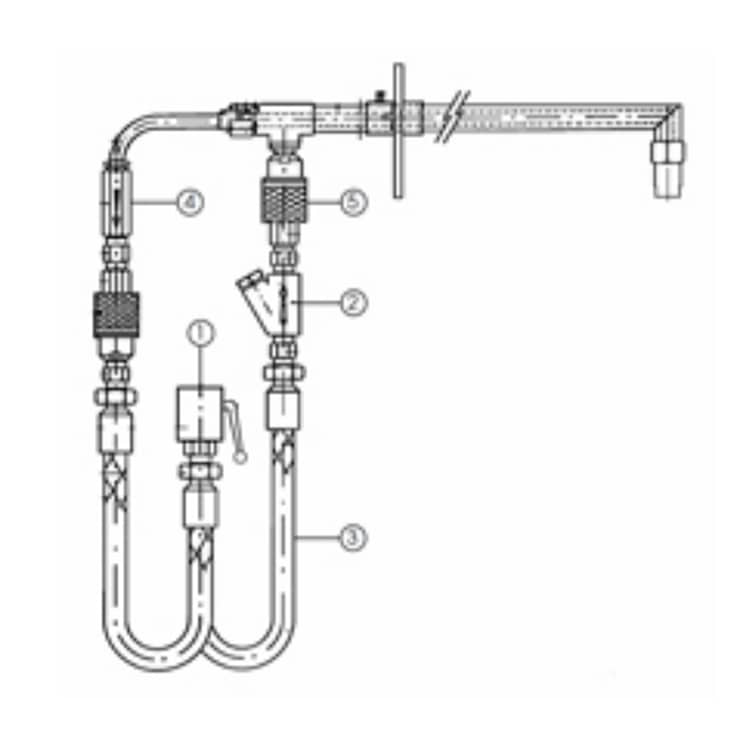

- High-Pressure Washers: These machines use pressurized water to dislodge and remove dirt, grease, and residues from conveyor belts and components. Nozzles and water pressure settings allow for versatility in cleaning different conveyor types.

- Conveyor Cleaning Brushes: Conveyor brushes are designed to sweep away loose debris and contaminants from the conveyor belt. They can be installed as part of an automated cleaning system.

- Automated Conveyor Washing Systems: These systems may include conveyor belt washers, where the entire conveyor passes through a washing chamber equipped with water jets, brushes, and drying units. These systems are efficient for continuous cleaning in high-volume production environments.

4. Considerations in Conveyor Washing:

- Material Compatibility: The cleaning method and agents should be compatible with the materials used in the conveyor system to avoid damage or degradation.

- Environmental Impact: Considerations should be made to minimize water usage and the environmental impact of cleaning agents. Water recycling systems may be implemented to reduce water consumption.

- Downtime: Depending on the industry and production schedules, conveyor washing activities should be planned to minimize downtime and disruptions to production.

- Regulatory Compliance: Industries with stringent hygiene standards, such as food processing and pharmaceuticals, must comply with regulatory requirements. Conveyor washing practices should align with these standards.

5. Regular Maintenance:

- Scheduled Cleaning: Establishing a regular cleaning schedule for conveyors is essential to prevent the accumulation of contaminants and ensure continuous operational efficiency.

- Inspections: Regular inspections of conveyor systems help identify wear and tear, damaged components, or areas that may require focused cleaning or maintenance.

Conveyor washing is a vital aspect of maintenance in industries where conveyors play a crucial role in material handling. It helps maintain cleanliness, prevent system malfunctions, and ensure compliance with hygiene and safety standards. The choice of cleaning methods and equipment depends on the specific requirements of the industry and the conveyor system in use.

Founded in 1982, Tecpro Australia has developed an enviable reputation for providing reliable and cost-effective technical solutions for a vast range of industrial applications. Products suitable for conveyor washing and screen washing application include:

* Spray Nozzles

* Design, Fabrication & Consulting

Our customers benefit from the following:

• Access to a broad range of quality solutions and technical advice

• Local sales support and customer service with a focus on integrity and honesty

• Over 30 years’ experience of providing expertise and solutions

• Quality European manufactured products.