CIP Tank Cleaning

CIP Tank Cleaning

What does a clean-in-place (CIP) system do?

A CIP Tank Cleaning and clean-in-place system automates the cleaning of the internal surfaces within a closed system. It enables tanks, plant equipment and pipelines to be thoroughly cleaned using special tank cleaning nozzles without the need for dismantling of the equipment.

What are the advantages of a CIP system?

When compared with manual cleaning processes, a CIP system can:

- improve the reliability and thoroughness of the cleaning process

- reduce the time and costs of manual labour

- avoid the risk of accidental recontamination upon reassembly of components

- reduce health and safety risks posed to staff by eliminating or reducing their contact with cleaning chemicals or entering confined spaces.

What factors need to be taken into account when designing an effective CIP system?

The effectiveness of a CIP tank cleaning system is affected by:

- the amount of time that the cleaning process runs for

- the temperature it operates at (too hot can ‘bake’ the soil on and too cool can compromise how well it cleans)

- the concentration of cleaning chemicals and sanitisers

- the velocity and flow rate of the water and/or cleaning agents

- the physical layout of the interior (for example the radius of pipe bends, the absence of dead ends and the inclusion of self draining properties affect how well the system works)

- how well the system is maintained (for example pump maintenance, valve maintenance and regular calibration checks are important).

The choice of system (including the components and the sequence established for automatic operation) depends upon the sanitation requirements in each situation.

What are the steps in a typical CIP cycle?

There are five steps involved in a typical CIP cycle. These are:

- Flushing in order to eliminate gross soiling

- Cleaning chemical wash to remove soil. Alkaline detergents are used to dissolve fat and proteins but other types of chemicals are also used, depending upon the soil needing to be removed.

- First rinse to remove cleaning chemicals.

- Acidic cleaning to neutralize any caustic chemicals remaining on the plant and to remove mineral deposits in the equipment.

- Final rinse to eliminate any residual cleaning chemicals.

What are the types of CIP systems?

CIP tank cleaning systems range from the simple to the highly complex.

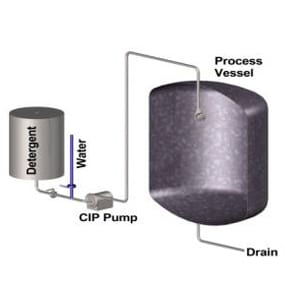

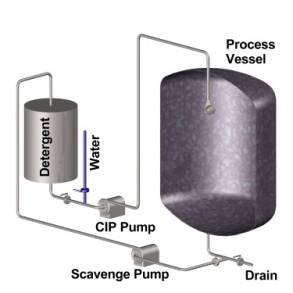

In general terms however, there are two main types of systems that are used: the single pass system and the recirculation system.

SINGLE PASS SYSTEM

Single pass systems do not reuse the cleaning solution and are often used for small systems and where heavy soiling is involved.

RECIRCULATION SYSTEM

Recirculation systems re-use the chemical solution. These systems are often suitable where light soiling is involved. Chemicals are topped up throughout the cycle as required until the cleaning cycle is finished. These types of systems can be less expensive to run because of lower chemical/water usage, however the initial capital outlay can be more significant.

How can the effectiveness of the CIP system be assured?

The components of a CIP system all need to work in sync to deliver effective cleaning performance.

Spray devices should deliver powerful, robust performance and where rotary sprays are used, the spray patterns should be set up to be predictable and repeatable, to ensure that all surfaces are cleaned properly.

Many CIP systems use microprocessors and computers to monitor, control and validate the cleaning process. This can provide objective and verifiable evidence that cleaning processes have been executed successfully.

What are the applications that can benefit from a CIP system?

CIP systems are used in a wide variety of applications including food production (dairy products, cook-in-sauce lines, cook-chill production, pastry production, cooked meat, short shelf-life food, sandwich manufacture etc), beverage production (including breweries), pharmaceutical production, chemical production and more.

Choosing the right CIP system

To deliver optimum performance, it is important to choose the system that suits your requirements and to set it up to deliver the cleaning outcomes required.

We recommend you seek professional advice from a CIP system professional at Tecpro Australia when making this important decision to ensure maximum effectiveness and a strong return on investment.